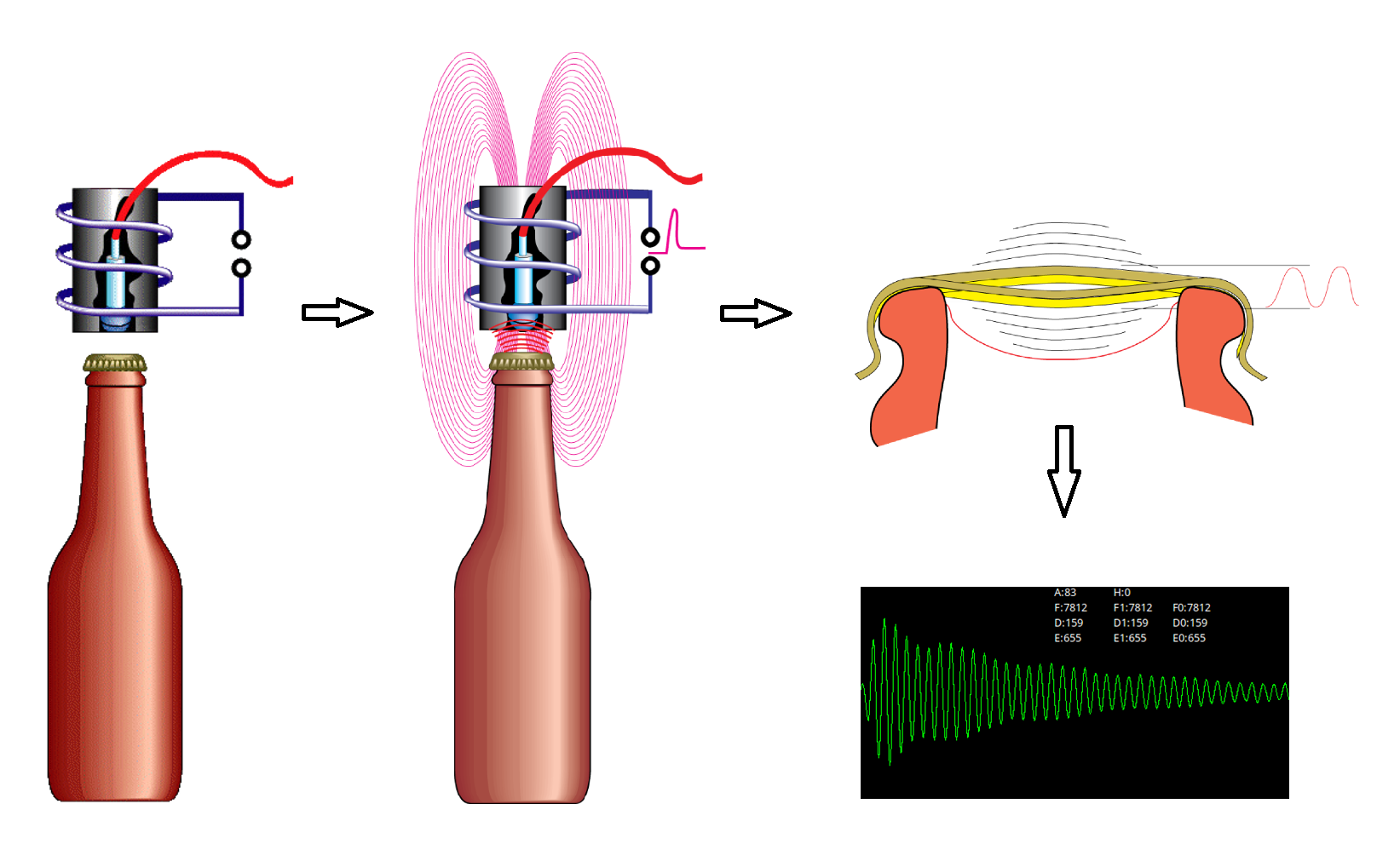

Beer Bottle Magnetoacoustic Leakage inspection EchoMeter achieves leakage inspection by actively exciting the cap of a beer bottle with electromagnetic field pulses and utilizing the principle of vibration waveforms captured by a high-precision acoustic sensor.

|

Scope of application:

|

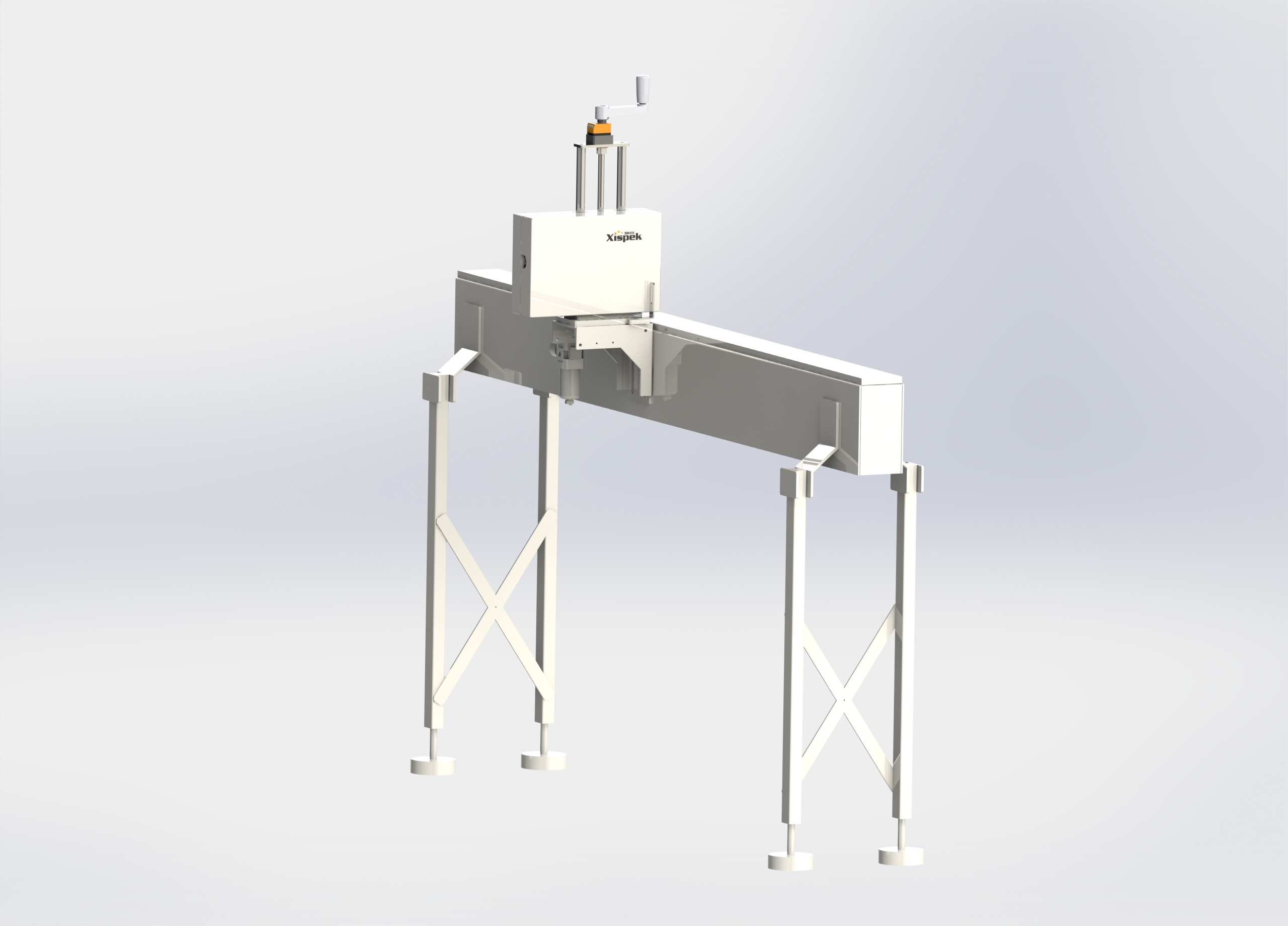

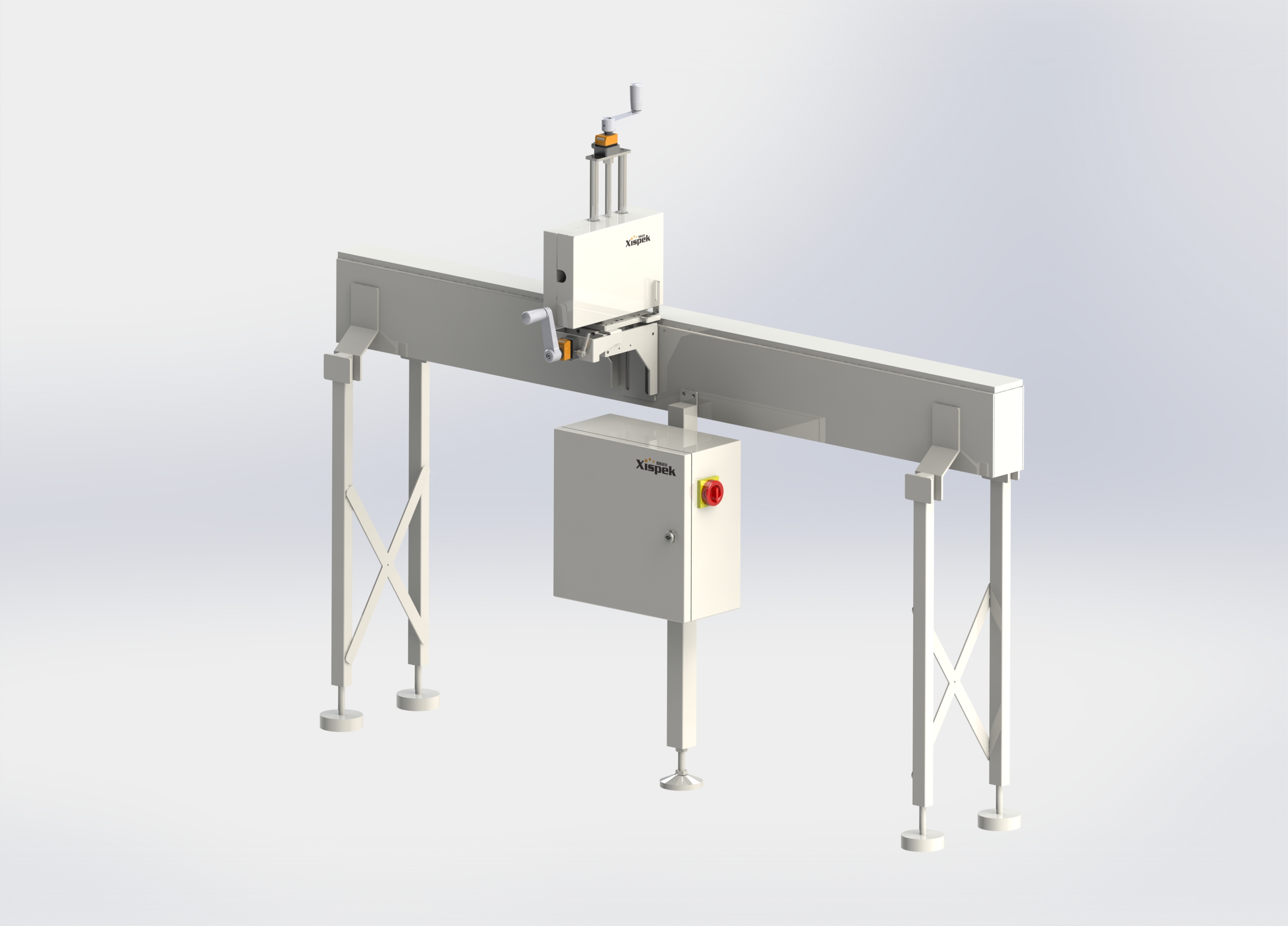

Installation position:

|

Missing cap

Missing cap

Leakage inspection

Leakage inspection

|

|

|

| Leakage | Deformation | Missing cap |

The EchoMeter working process is accomplished by the following steps:

1. An electromagnetic coil passes a strong electric current in a very short period of time.

2. The coil creates an electromagnetic pulse that "hits" the bottle cap.

3. The cap vibrates under the electromagnetic pulse and makes a sound.

4. Acquisition of waveforms by acoustic sensors

5. Analyze the waveform through the inspection software to determine the leakage of the bottle.

Non-contact measurement

Non-contact measurement

Optimized sensor design to reduce the impact of bottle height errors on detection

Optimized sensor design to reduce the impact of bottle height errors on detection

Inspection module IP65 protection level for various environment

Inspection module IP65 protection level for various environment