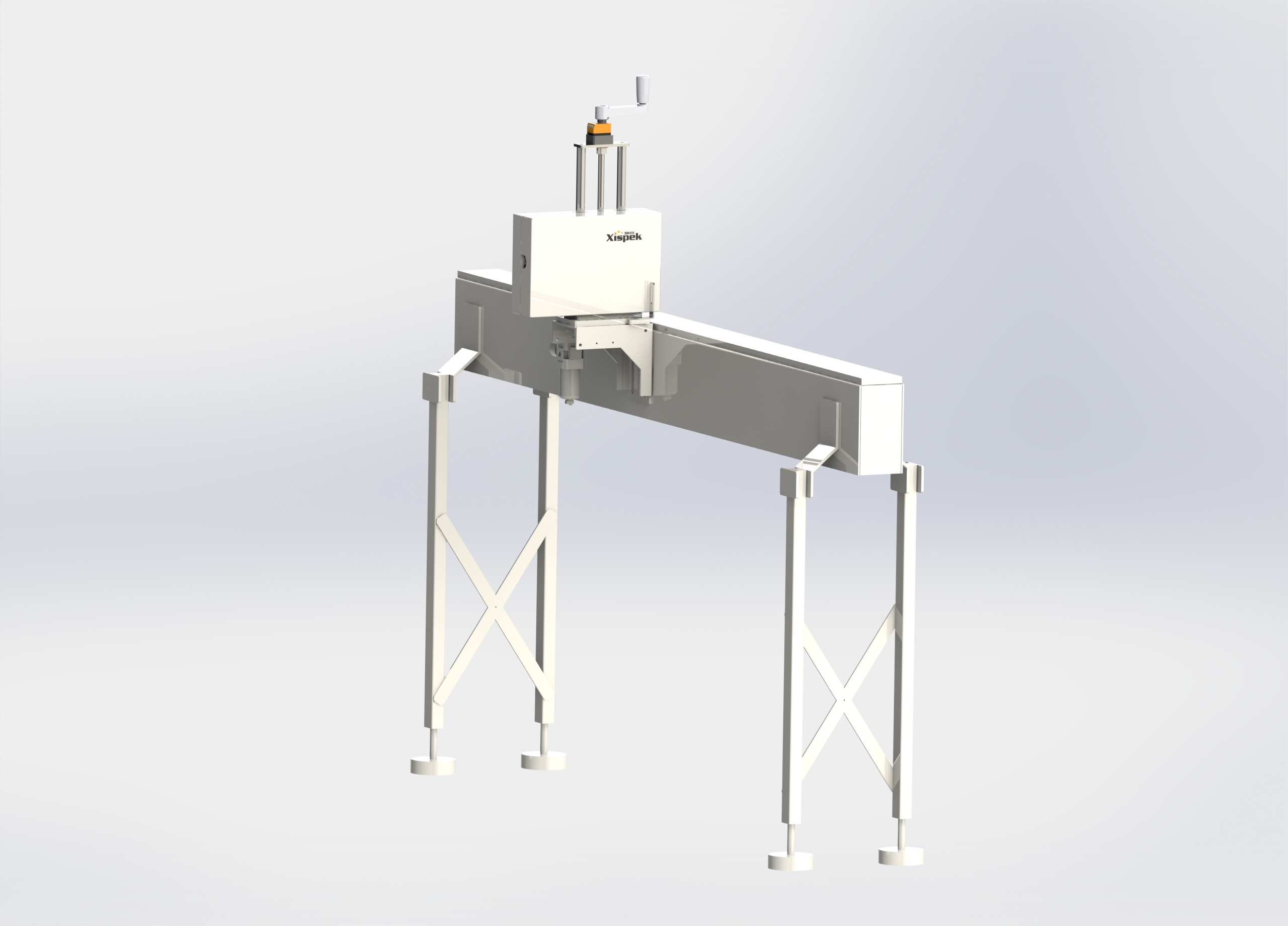

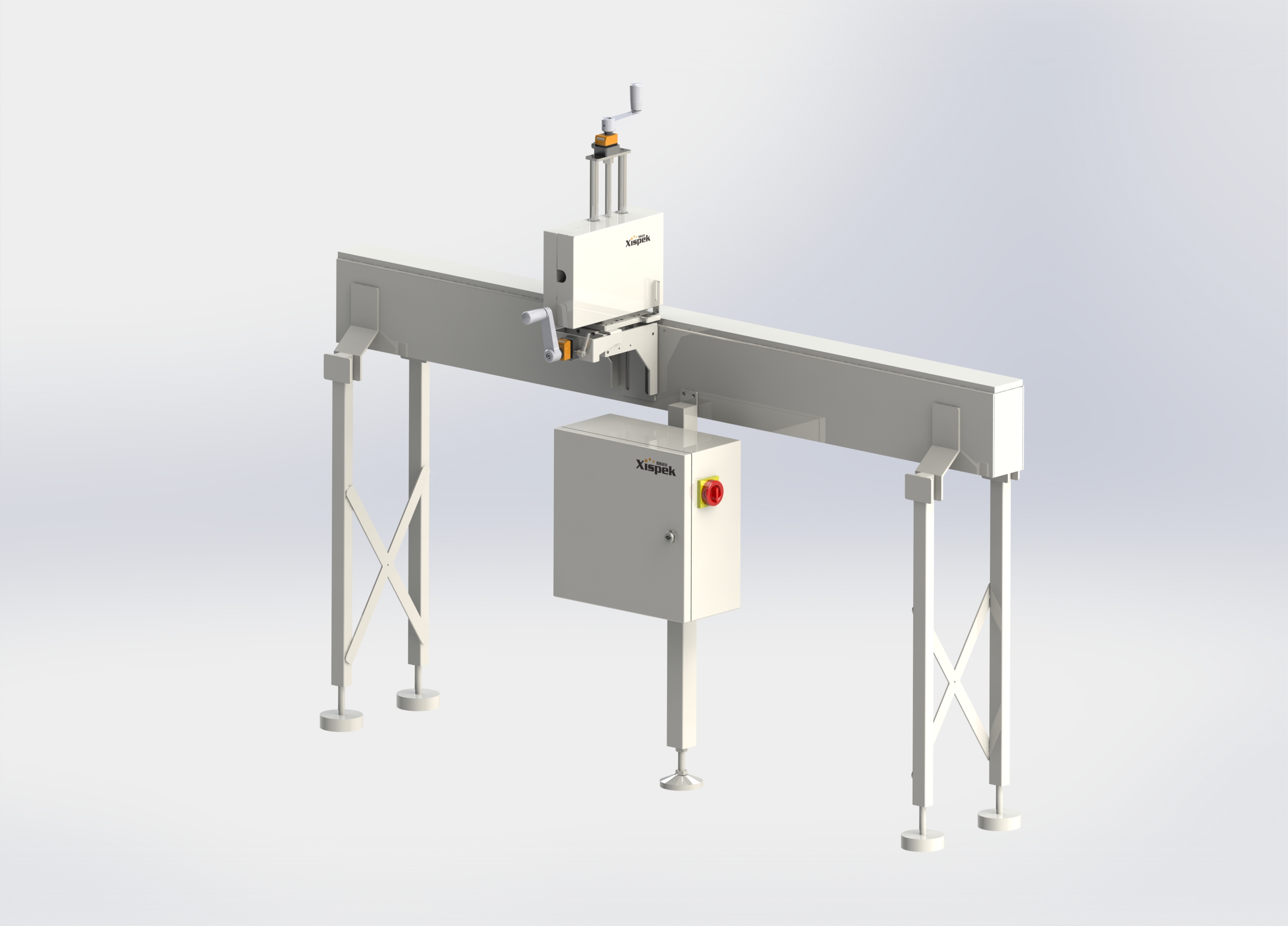

Can Leakage inspection LaserMeter inspects the seal of a can by how much the top cover deforms under pressure. It is usually installed after the pasteurizer to ensure that beverages or other substances in the can are not contaminated or spoiled by pressure leaks.

|

Scope of Application:

|

Installation position:

|

Pressure deformation detection

Pressure deformation detection

Can Leakage inspection LaserMeter inspects the sealing of cans by the degree of deformation of the top cover under pressure. Leaks are detected in a timely manner and sub-standard cans are separated to ensure that only qualified products enter the market.

Utilizes XispVision® universal inspection software platform

Utilizes XispVision® universal inspection software platform

Dual detection head design, stable inspection

Dual detection head design, stable inspection

Sensors with IP67 protection level

Sensors with IP67 protection level

Reliable and cost-effective

Reliable and cost-effective