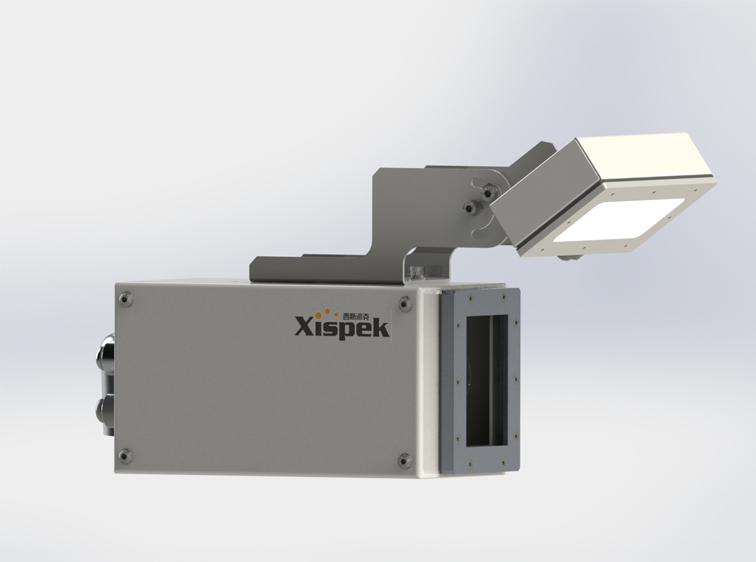

Code inspection (LBI-Code) is a kind of module installed after the printer to inspect the code of the product, mainly for the inspection of various defects of the code. The module adopts high-speed industrial camera and independent XispVision® general inspection software platform to accurately and efficiently identify the code and reject the defective products. Overall design is compact and flexible, the angle of the light source can be adjusted, and has a high degree of adaptability to the inspection of a variety of codes.

|

Scope of application:

|

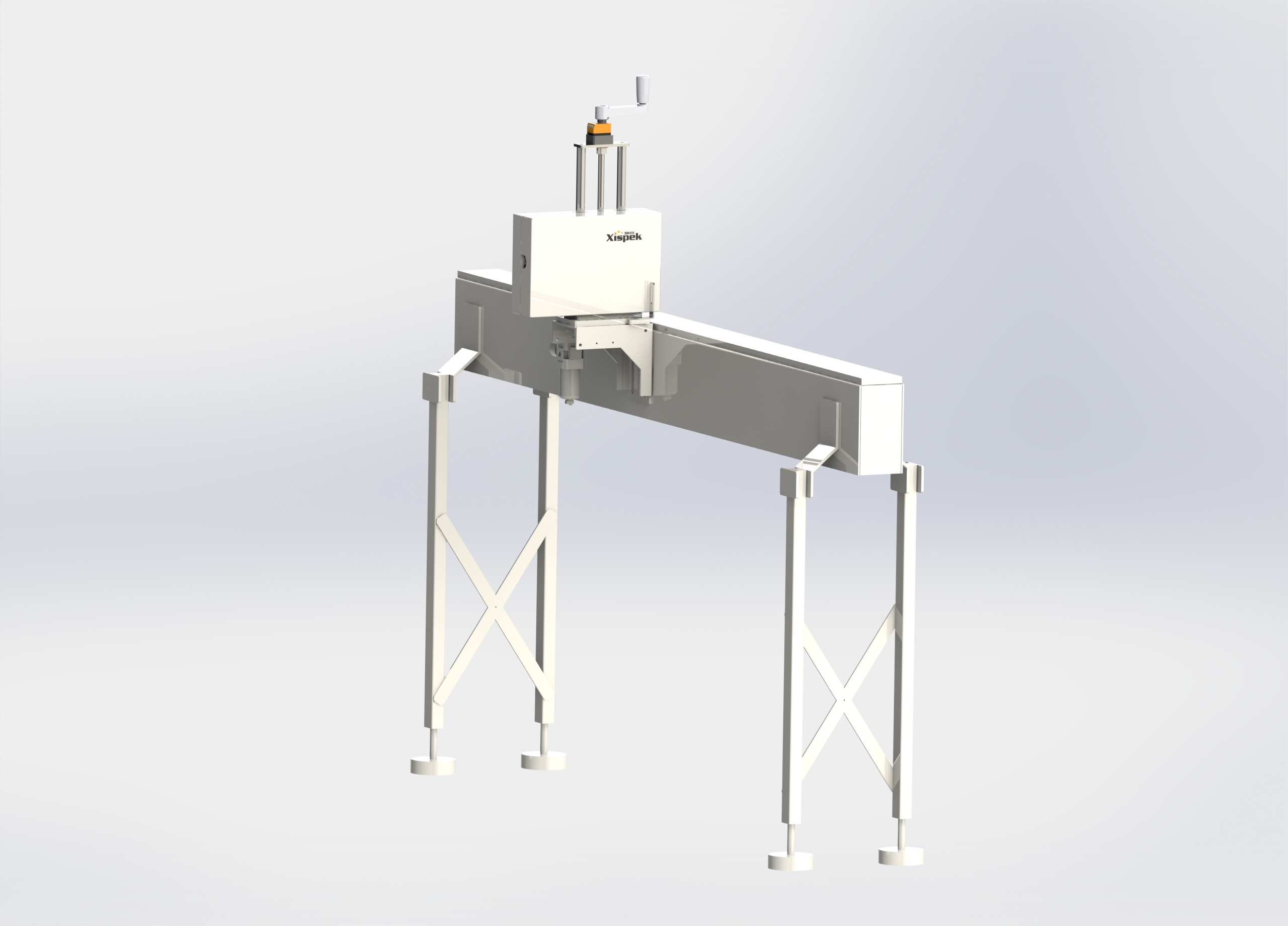

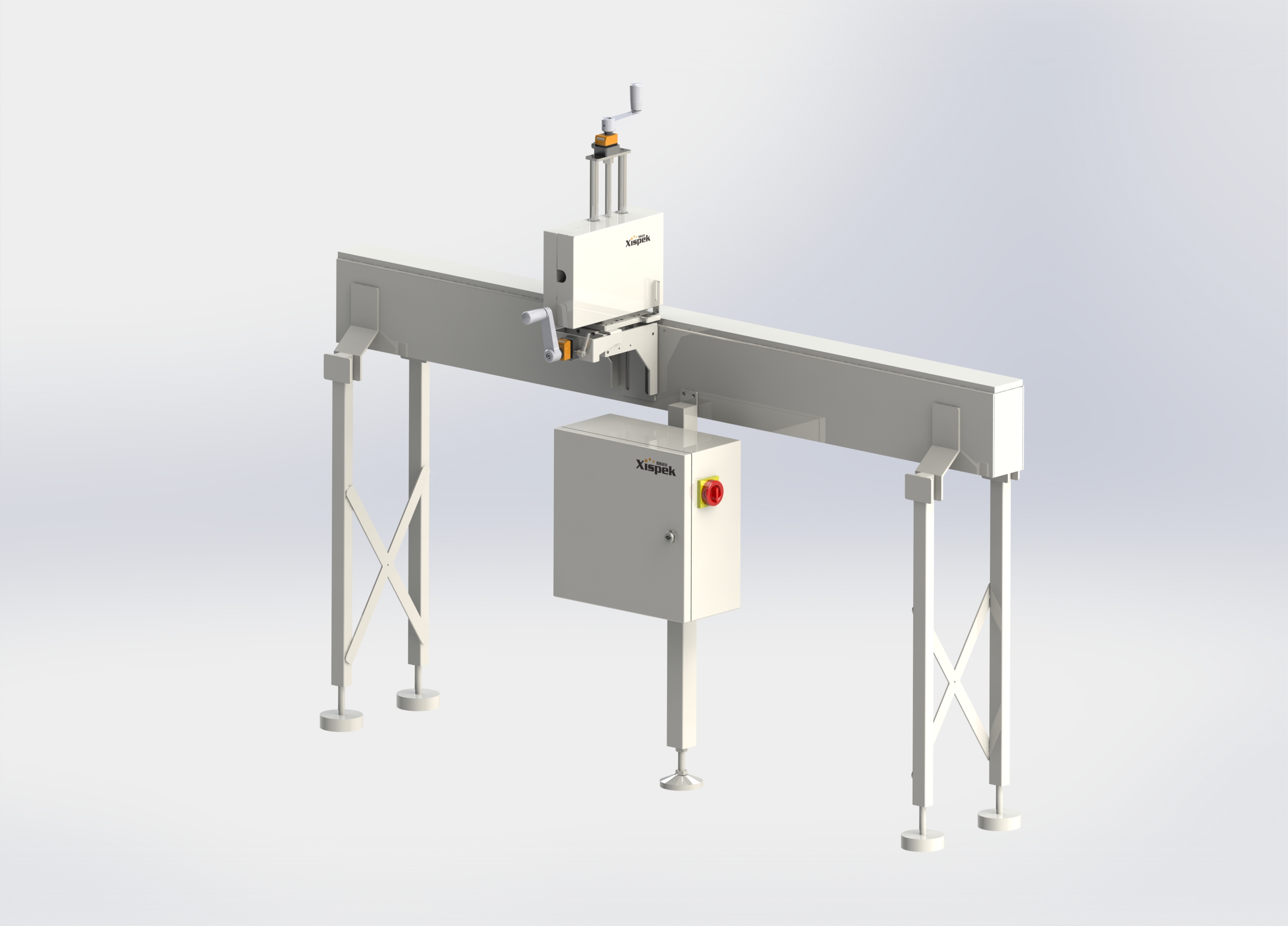

Installation position:

|

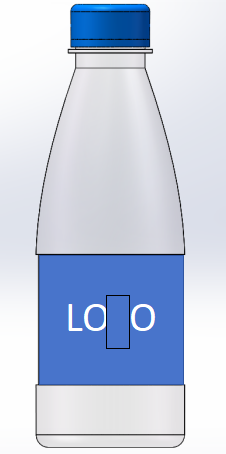

Jet code present or absent

Jet code present or absent

Character missing

Character missing

Date recognition

Date recognition

Shift recognition

Shift recognition

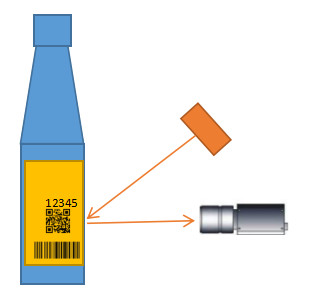

Barcode, 2D code reading

Barcode, 2D code reading

OCR

OCR

|

|

|

|

Missing Code |

Missing QR Code |

Missing Barcode |

|

|

|

|

Missing dates |

|

|

The code inspection system is mainly used to inspect the code of various products on the production line and reject the unqualified products to prevent the defective products from flowing into the market and causing customer complaints.

It can be applied to different material surfaces (paper package, metal, plastic, etc.) and different coding equipments (ink jet, laser jet and carbon dioxide, etc.).

According to different coding quality, it can realize the functions such as the presence or absence of coding, missing characters, date recognition, shift recognition, barcode, code reading, etc.

Coding inspection system adopts modular structure, according to the speed of the production line can be selected with different control centers and other functions of the module, but also can be configured at the same time more than one detection module for multiple production lines, more than one code inspection, the overall has a high degree of adaptability, flexibility, stability.

Adpots XispVision® universal inspection software platform

Adpots XispVision® universal inspection software platform

Precise rejection with controlled intensity

Precise rejection with controlled intensity

Compact design for easy integration

Compact design for easy integration

Inspection module with IP65 protection level

Inspection module with IP65 protection level

Modular design, flexible expansion according to the needs of the production line

Modular design, flexible expansion according to the needs of the production line

suitable for a wide range of material surfaces (paper packages, metals, plastics, etc.)

suitable for a wide range of material surfaces (paper packages, metals, plastics, etc.)

Suitable for a wide range of printers (ink, laser, CO2, etc.)

Suitable for a wide range of printers (ink, laser, CO2, etc.)