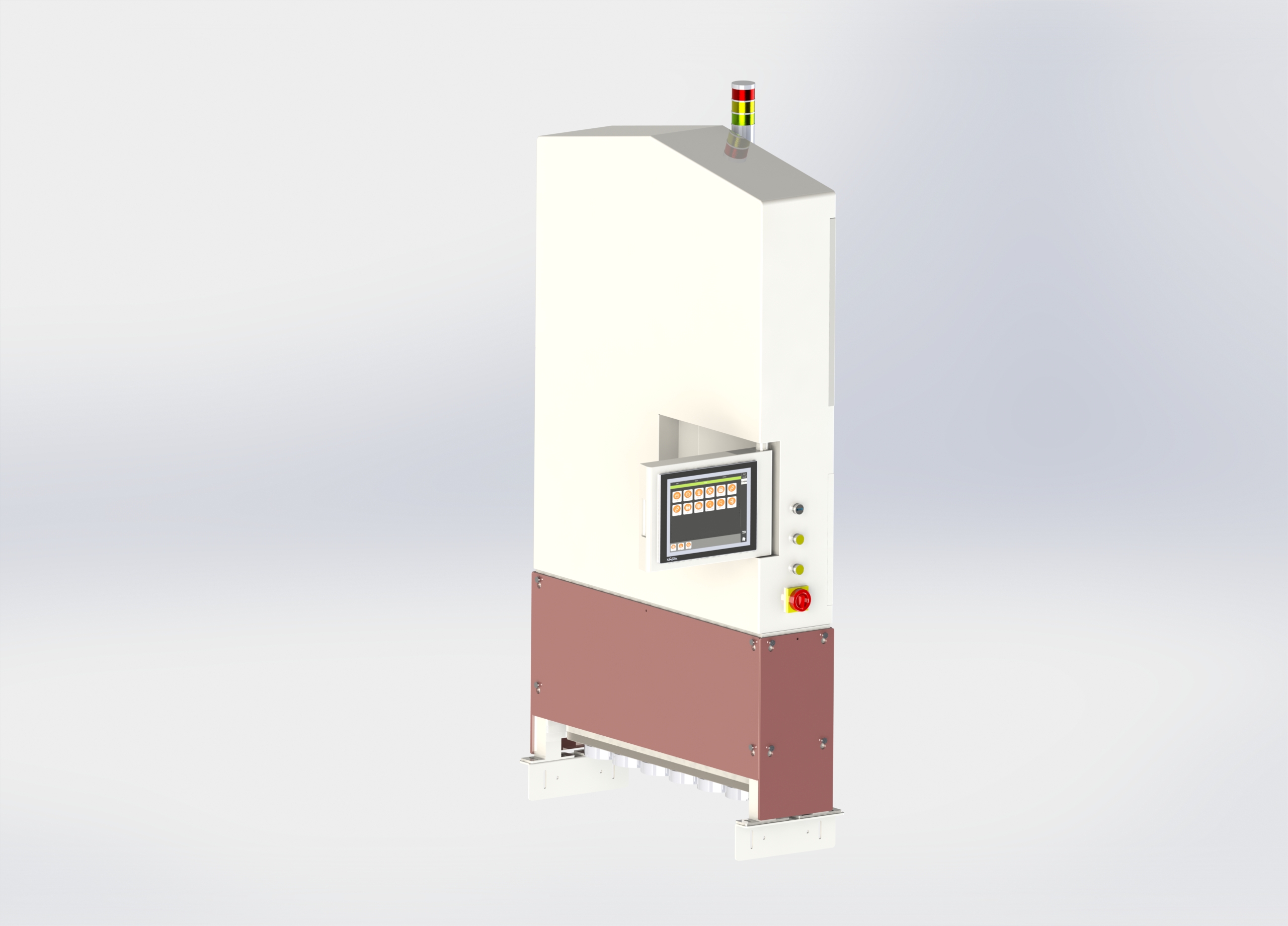

CaCooka InLine is a professional inspection device for cookie appearance inside the sandwich machine. It adopts high-precision sensors and intelligent algorithms to quickly and accurately inspect cookies for multiple defects such as missing top cover, reversal, overfilling, cracking, missing corner, and dimensions and other defects, so as to ensure cookies' quality.

|

Scope of Application:

|

Installation position:

|

Overfilling

Overfilling

Top cover Missing

Top cover Missing

Reversal

Reversal

Cracking

Cracking

Missing corner

Missing corner

Size

Size

|

|

|

|

Top cover Missing |

Reversal |

Overfilling |

|

|

|

|

Cracking |

Missing corner |

Size |

Xispek offers two different sandwich cookie inspection systems, the CaCooka, which is mounted on the conveyor belt behind the sandwiching machine, and the CaCooka InLine, which is mounted directly inside the sandwiching machine.

|

|

CaCooka |

CaCooka InLine |

|

Installation position

|

On the conveyor belt behind the sandwiching machine |

Inside the sandwiching machine |

|

Pusher

|

Independent Pneumatic pusher

|

Using the rejection device in the sandwiching machine

|

|

Design

|

Embedded Touch Screen Design |

Higher height, touch screen cantilever design |

The CaCooka InLine, like the CaCooka, offers several advantages. First of all, it uses a combination of advanced laser sensors and visual recognition technology to quickly and accurately detect all defects in sandwich cookies, including missing top cover, reversal, overfilling, cracking, missing corner, and dimensions defects. All defective products are rejected online to a defective product collection conveyor through a pusher to ensure product quality meets the standard. CaCooka InLine has a humanized integrated design. It can be applied to different filling colors, base cake colors, and specifications of sandwich cookies, realizing the function of one-button changeover, which reduces the time for customers to changeover and saves the labor and time cost.

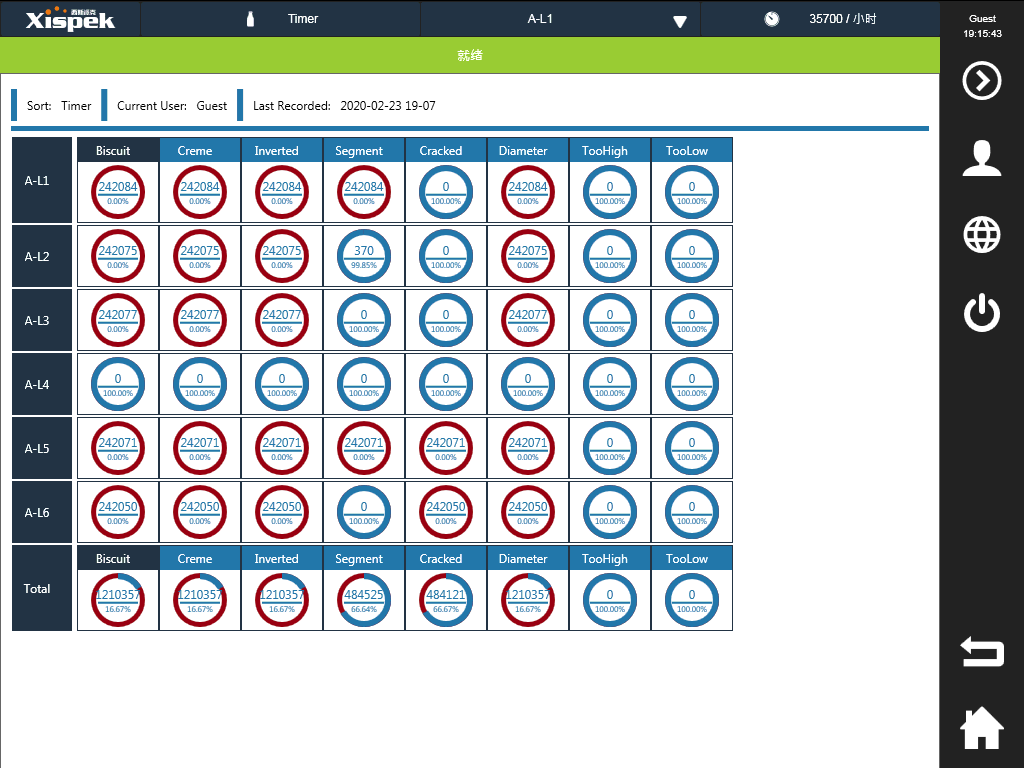

CaCooka InLine is able to count and record daily inspection data in real time, which can help manufacturers to carry out quality management and process improvement, and provides multiple communication protocol interfaces to facilitate data collection by customers. In conclusion, CaCooka InLine, as the inspection equipment for sandwich cookies, plays an important role in improving production efficiency and product quality. Its advantages of high precision, speed and accuracy, adaptability and data recording and analysis enable manufacturers to better control product quality and provide high quality sandwich cookie products that meet consumer expectations.

The CaCooka InLine 6600 is capable of inspecting up to 6 lanes of cookies at the same time, with an inspection speed of up to 600 biscuits/minute per lane. Of course we can customize the solution according to the number of product lanes in the customer's production line.

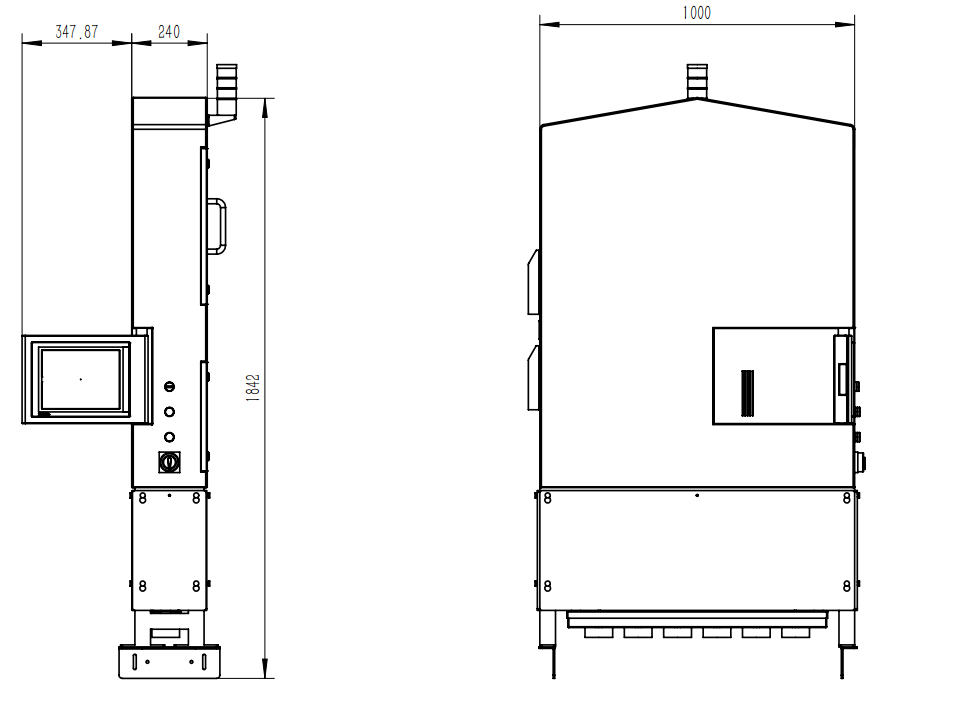

The system is only 30 cm thick and can be easily integrated into space-constrained sandwiching machines

The system is only 30 cm thick and can be easily integrated into space-constrained sandwiching machines

The entire inspection hardware is integrated in the electrical cabinet to save space

The entire inspection hardware is integrated in the electrical cabinet to save space

Dual fan convection, camera with heat sink

Dual fan convection, camera with heat sink

Single LED per pass, IP65 sealed for maintenance free design

Single LED per pass, IP65 sealed for maintenance free design

Long working distance to ensure clean equipment standards

Long working distance to ensure clean equipment standards

Sensors can be cleaned directly during the production

Sensors can be cleaned directly during the production

Stable triggering and measurement

Stable triggering and measurement

Ultra-high measurement accuracy, repeatability <0.02mm

Ultra-high measurement accuracy, repeatability <0.02mm

Camera sealed inside IP65 inspection module

Camera sealed inside IP65 inspection module

Vision components are kept away from cookies, hygienic grade design

Vision components are kept away from cookies, hygienic grade design

The light source can be adjusted up and down, easy for production and maintenance

The light source can be adjusted up and down, easy for production and maintenance

Individual LED light source for each channel, maintenance-free

Individual LED light source for each channel, maintenance-free

Integrated touch screen operation, convenient and quick

Integrated touch screen operation, convenient and quick

Adopts XispVision® universal inspection software platform

Adopts XispVision® universal inspection software platform

Provides detailed statistics

Provides detailed statistics

Unified communication protocol data interface is convenient for customers to collect data (OPC-UA/Modbus-TCP)

Unified communication protocol data interface is convenient for customers to collect data (OPC-UA/Modbus-TCP)

The whole machine is made of all stainless steel, food-grade hygiene standard design

The whole machine is made of all stainless steel, food-grade hygiene standard design

High inspection efficiency and inspection accuracy

High inspection efficiency and inspection accuracy

Compact design for easy integration

Compact design for easy integration

IP65 protection level, adapt to various environments

IP65 protection level, adapt to various environments

Compatible with all types of sandwich cookies, one-click changeover

Compatible with all types of sandwich cookies, one-click changeover

Sandwich Cookie inspection CaCooka 6600

Sandwich Cookie inspection CaCooka 6600

Control center

Control center

● Integrated Control Center