Empty can inspection system Nulla typically use machine vision technology, combined with high-speed cameras and image processing algorithms, to perform a full range of quality inspections on empty cans, including appearance defects, dents, scratches, deformations, and other issues. It also ensures the sealing performance of the can finish by detecting any damage or deformation to avoid leakage during the filling process.

|

Scope of Application:

|

Installation Location:

|

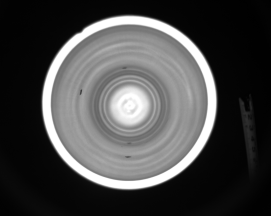

Can finish inspection

Can finish inspection

Can inner wall inspection

Can inner wall inspection

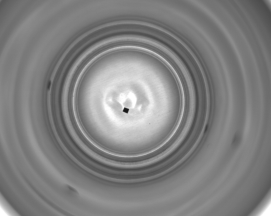

Can bottom inspection

Can bottom inspection

Dirty/ foreign matter at can neck, etc

Dirty/ foreign matter at can neck, etc

|

|

|

Can finish inspection |

Tank bottom inspection |

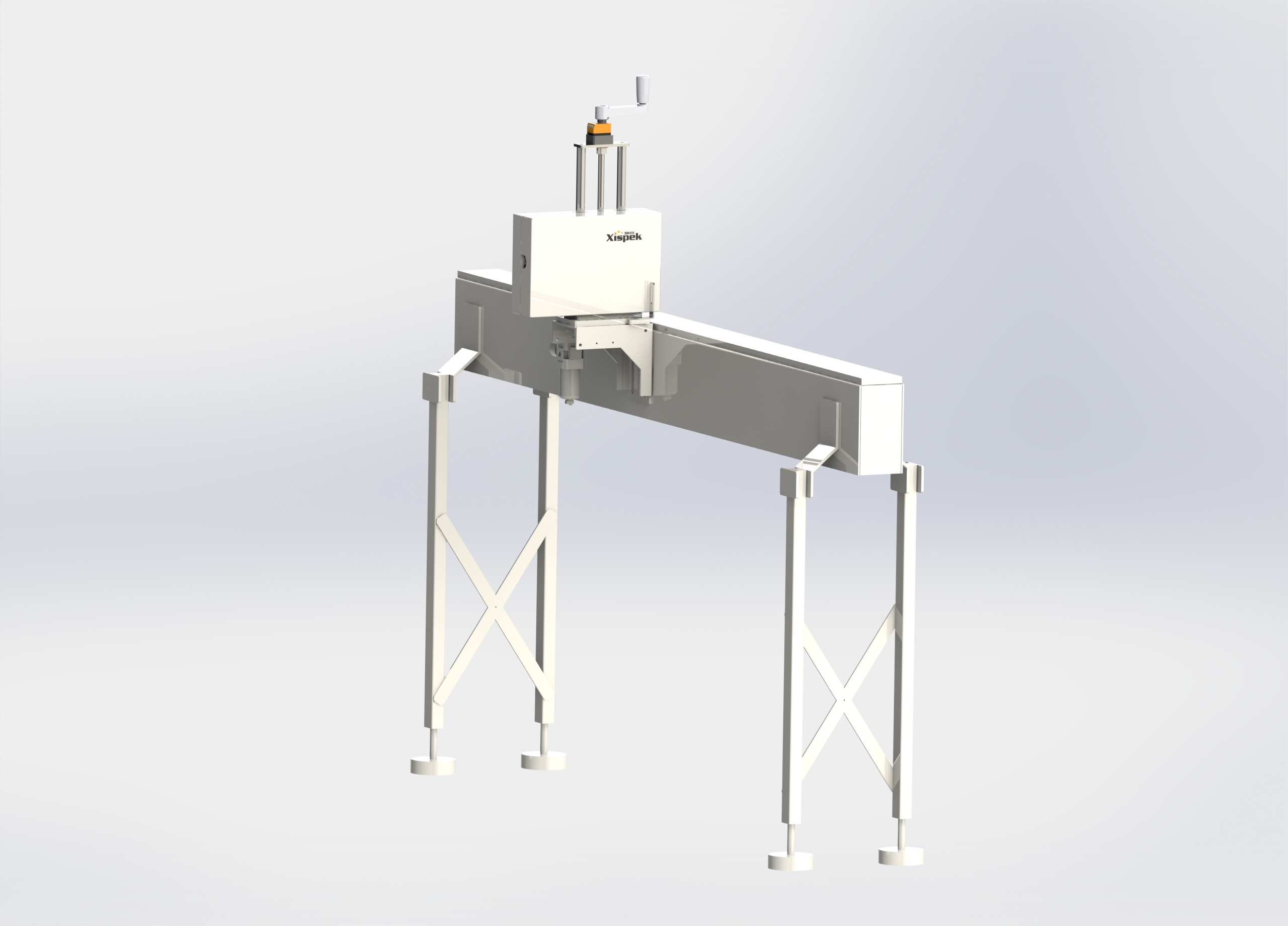

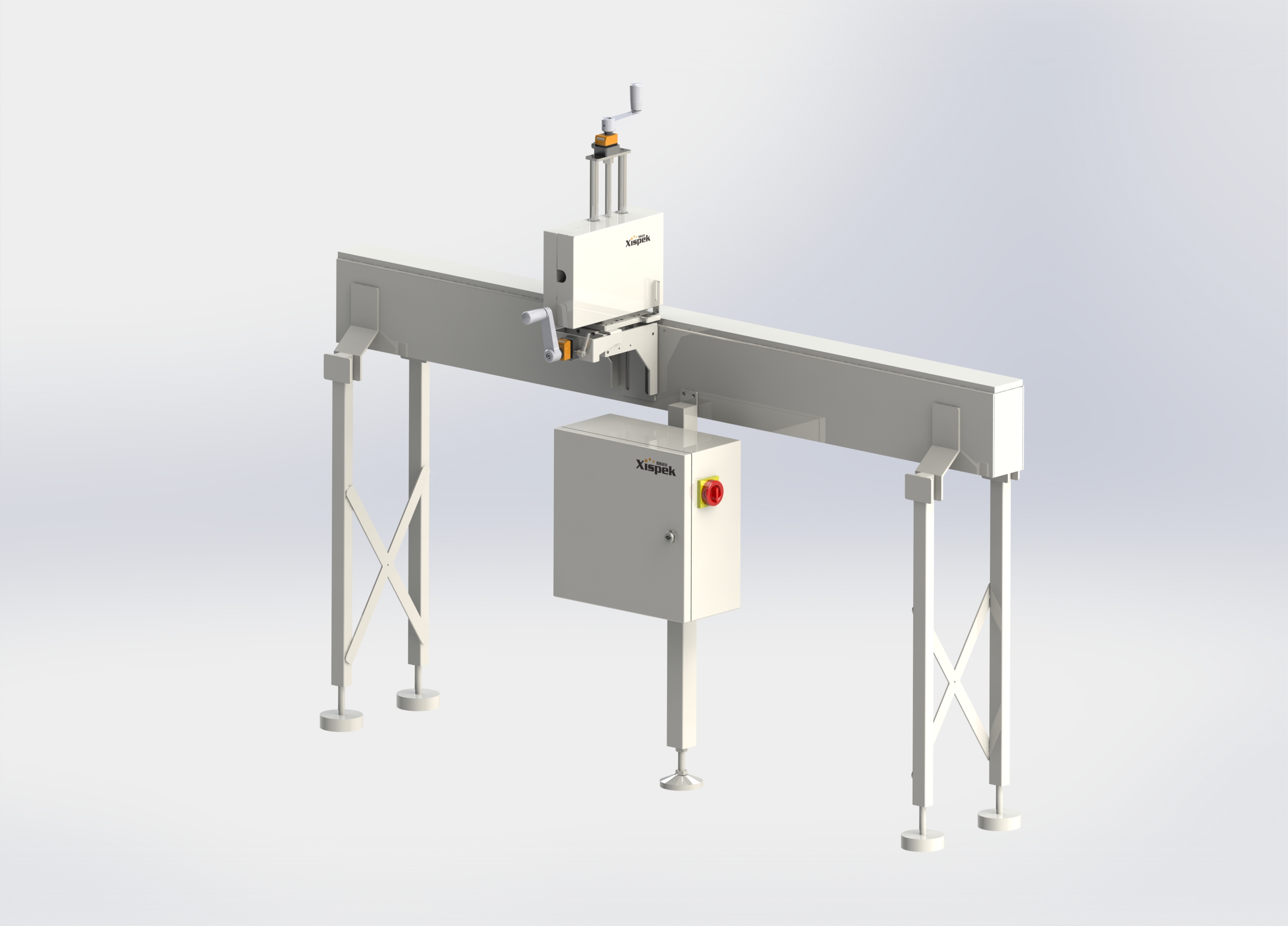

The Nulla empty can inspection is installed in the single lane before filling. In case of high speed production lines this single lane should have a vacuum adsorption system to hold the empty cans firmly on the conveyor belt to avoid sliding of the cans. The system uses a high-speed camera to accurately photograph each can and detect quality problems such as breakage, deformation, stains, etc. The system can also be used to check the quality of the cans. It recognizes minute defects and enables fast and accurate rejection on high-speed production lines, often using gas injection or mechanical rejection to remove sub-standard empty cans to a designated area. Empty can inspection Nulla has a lifting and adjusting mechanism and digital display device, can also be equipped with electric adjusting mechanism, applicable to all types of cans. It also has the ability to process images quickly, and can complete the inspection of each can in milliseconds. With the option of different control centers, inspection speeds of up to 120,000 cans/hour can be achieved, making it ideal for high-speed production lines. The empty can inspection Nulla has been rigorously tested and validated for reliability and stability.

Adopts XispVision® universal inspection software platform

Adopts XispVision® universal inspection software platform

High inspection efficiency and accuracy

High inspection efficiency and accuracy

Compact design for easy integration

Compact design for easy integration

Inspection module with IP65 protection level

Inspection module with IP65 protection level

Manual and automatic adjustment mechanism optional

Manual and automatic adjustment mechanism optional

Compatible with all types of cans

Compatible with all types of cans