Xispek

Search

Conversion Products

|

|

|

|

|

|

|

|

|

Copyright Suzhou Xispek Inspection Technology Co.,Ltd

Filing number:

Technical support: SunCloud Network

✕

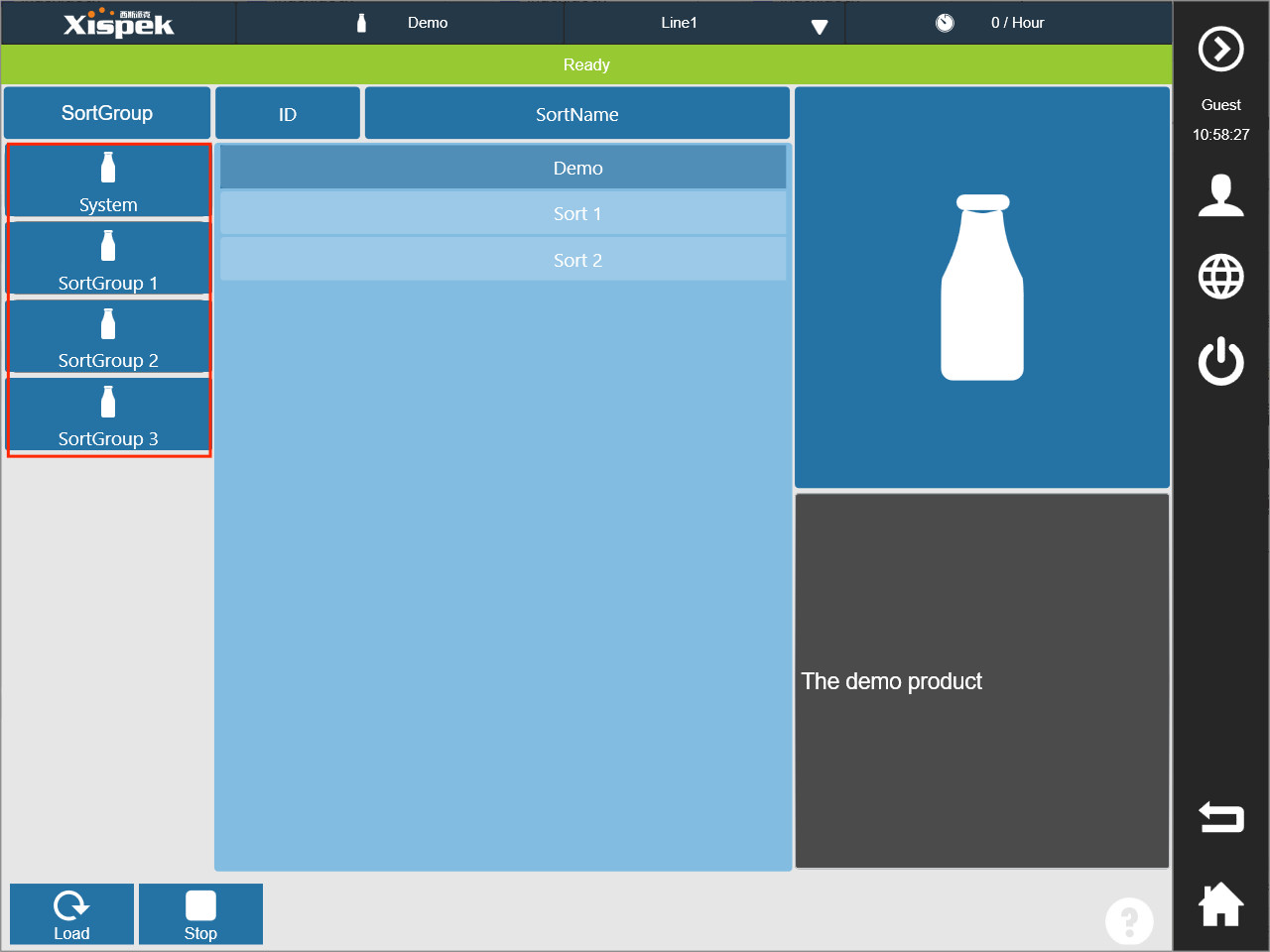

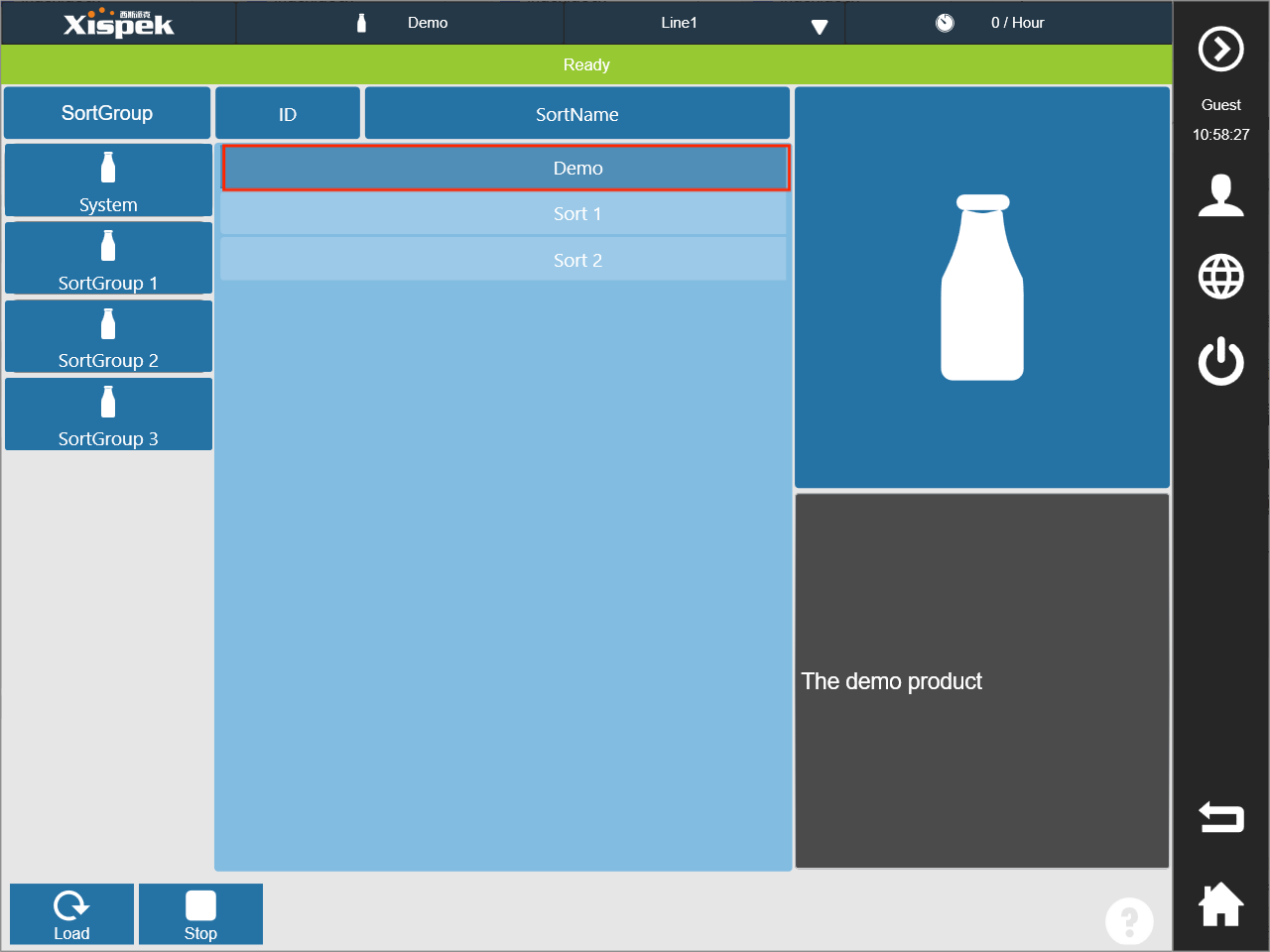

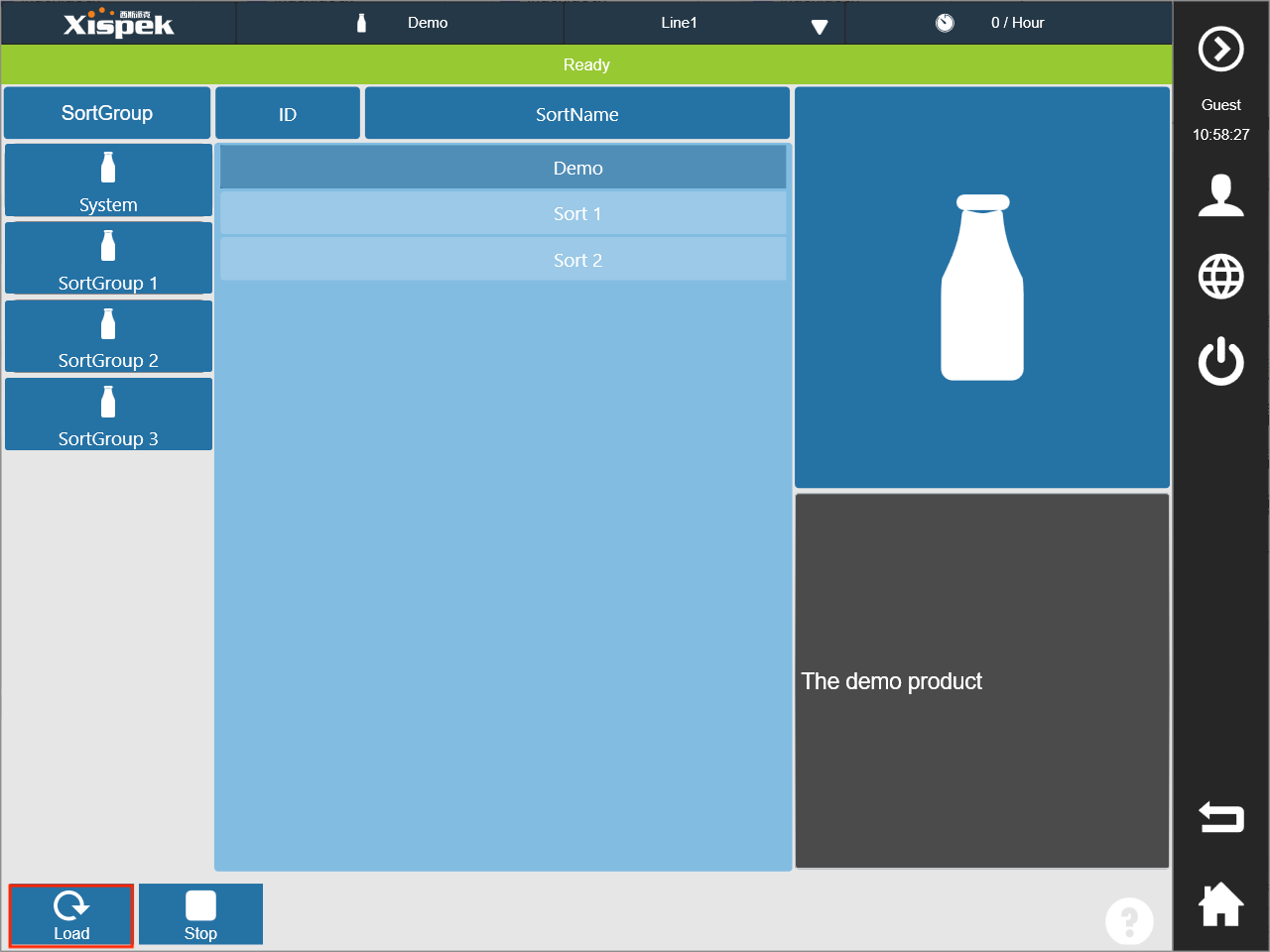

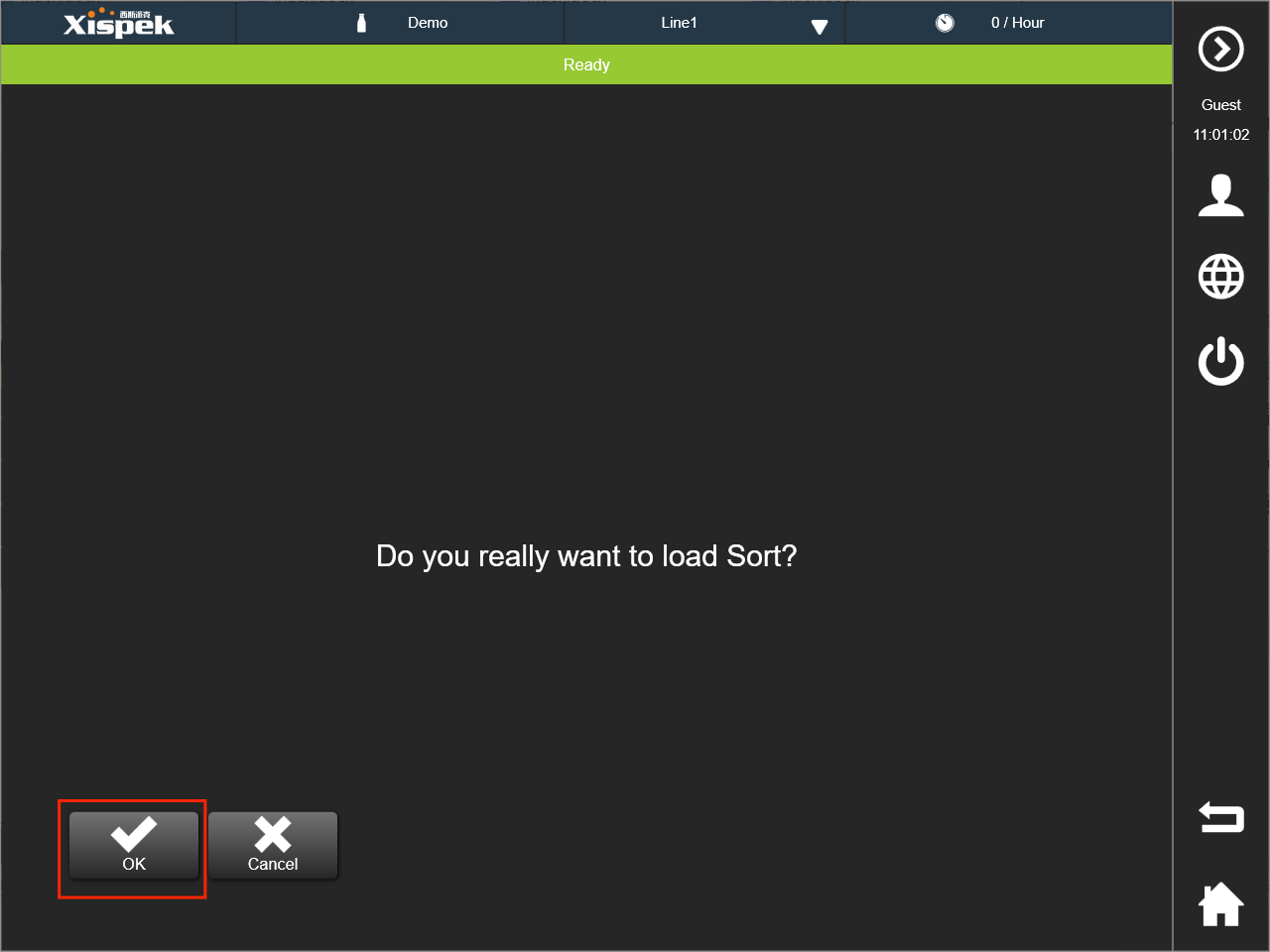

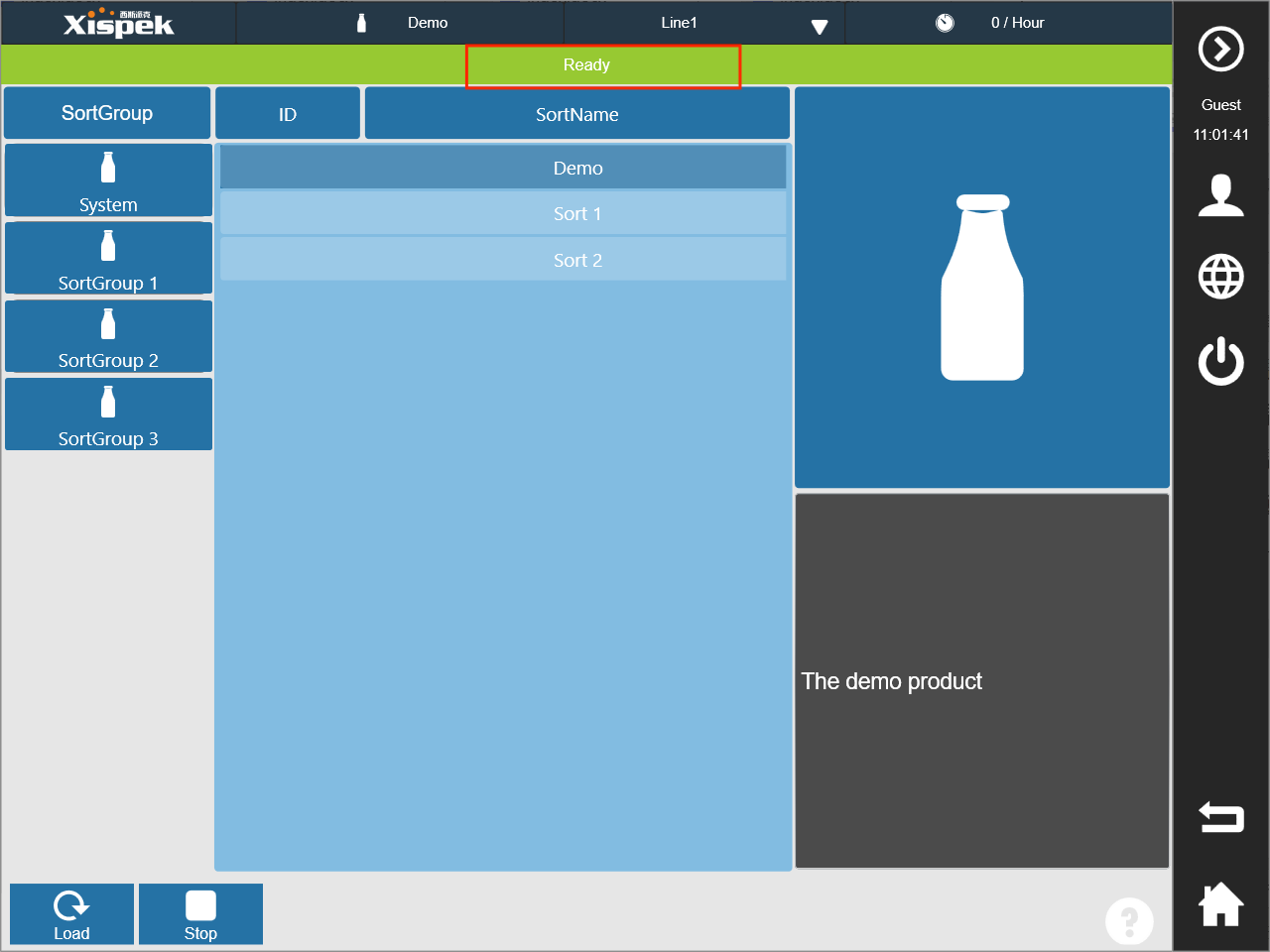

Click Load Sort button

Click Load Sort button