XispVision®: A Universal Inspection Platform Software Suite

More than just vision

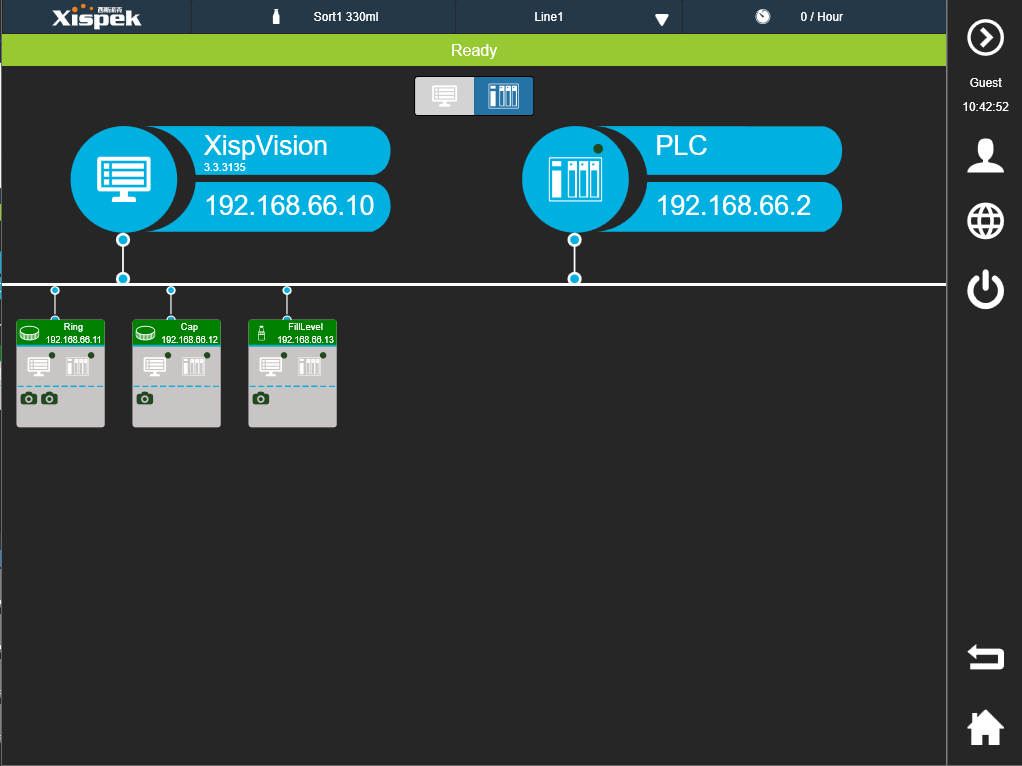

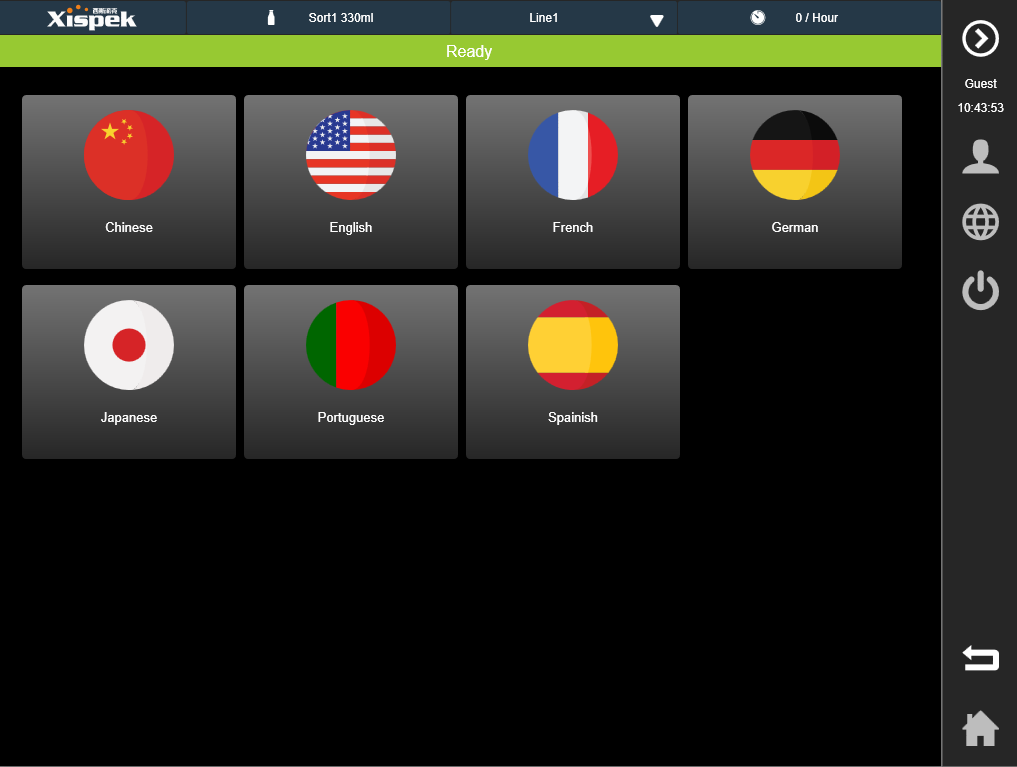

XispVision® is the universal inspection software platform on which all Xispek inspection systems, including smart cameras, are based. Whether it's a standard control center or an integrated non-standard control center, whether it's an empty bottle inspection full bottle inspection, or sandwich inspection, all inspection tasks are performed using XispVision® software. In addition, Xispek can provide XispVision® software to other equipment manufacturers to help them produce their own vision and inspection systems.

XispVision® is an inspection software with a common interface, complete image algorithm and tracking control system.

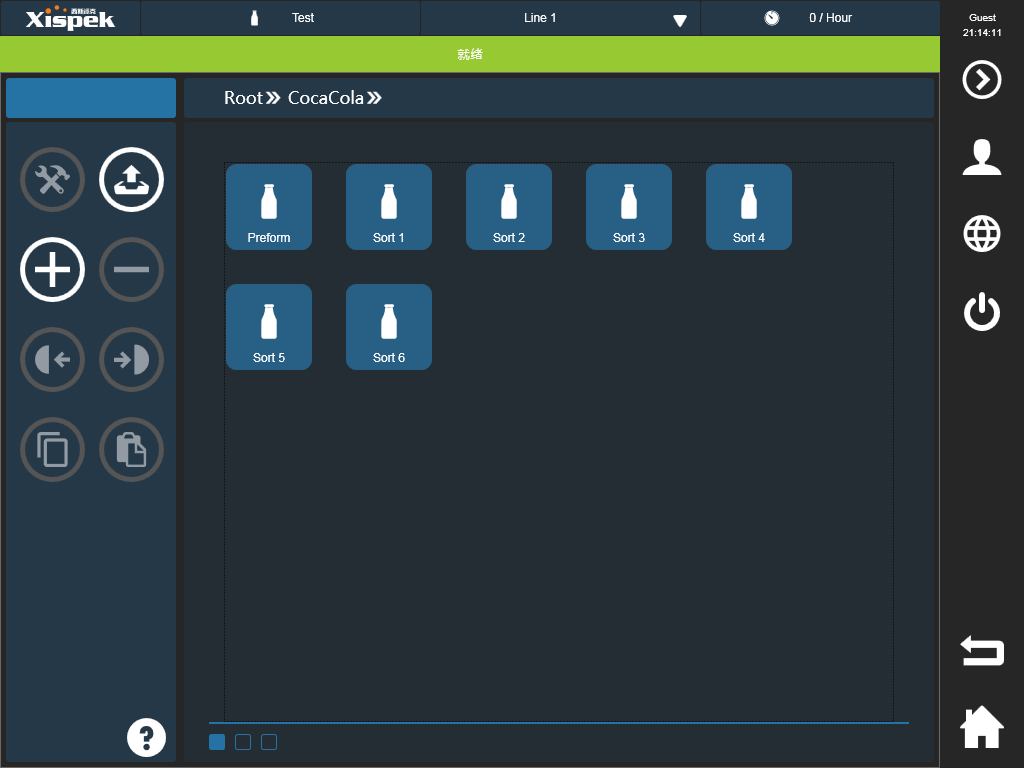

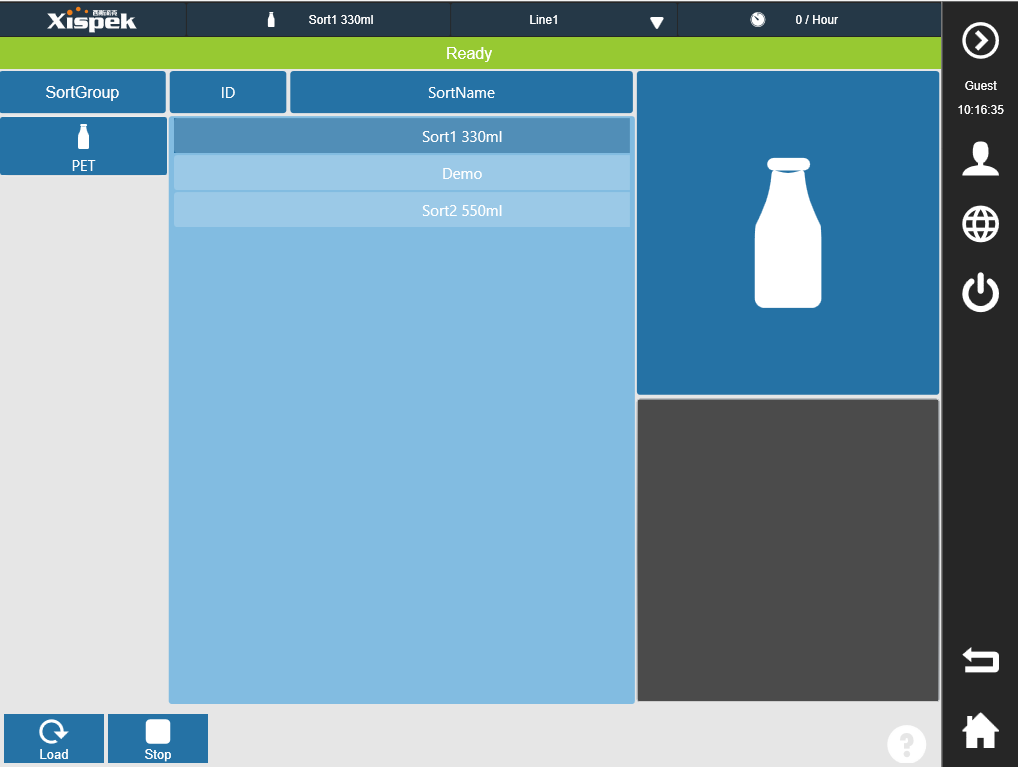

Recipe Management:

Product grouping management

Product grouping management

Unlimited number of recipes

Unlimited number of recipes

Testing Statistics

Testing Statistics

Substatistics

Substatistics

Production and service statistics

Production and service statistics

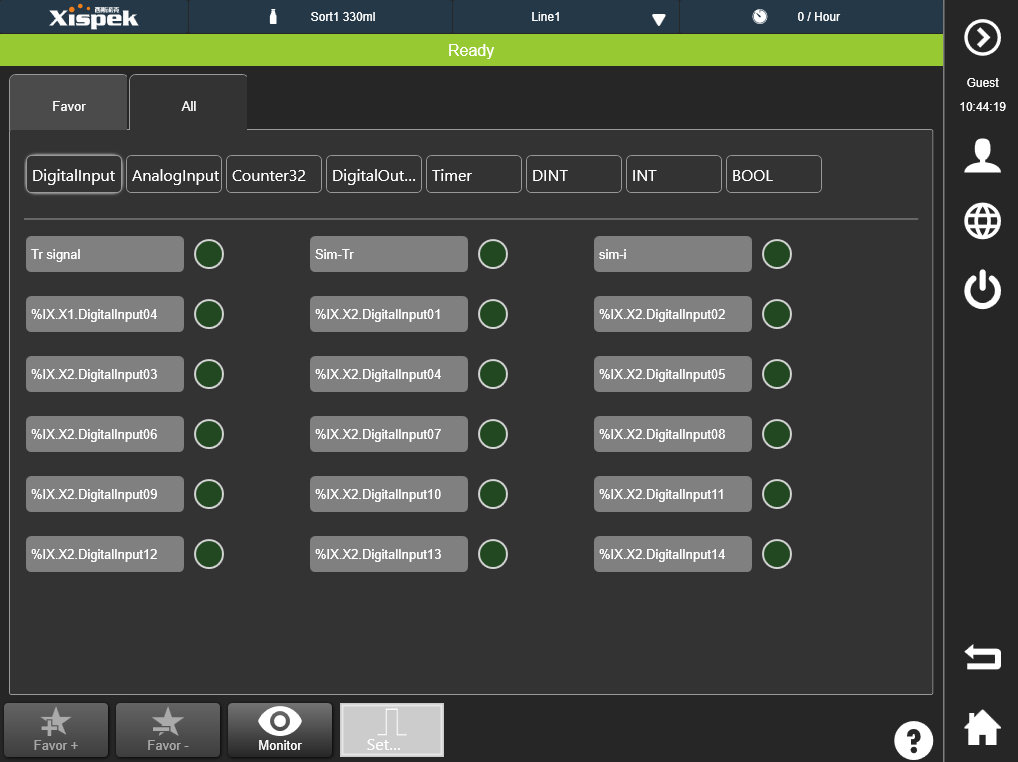

Three diagnostic modes

Three diagnostic modes

Quickly locate the problem

Quickly locate the problem

Online parameter modification

Online parameter modification

Remote offline calculation

Remote offline calculation

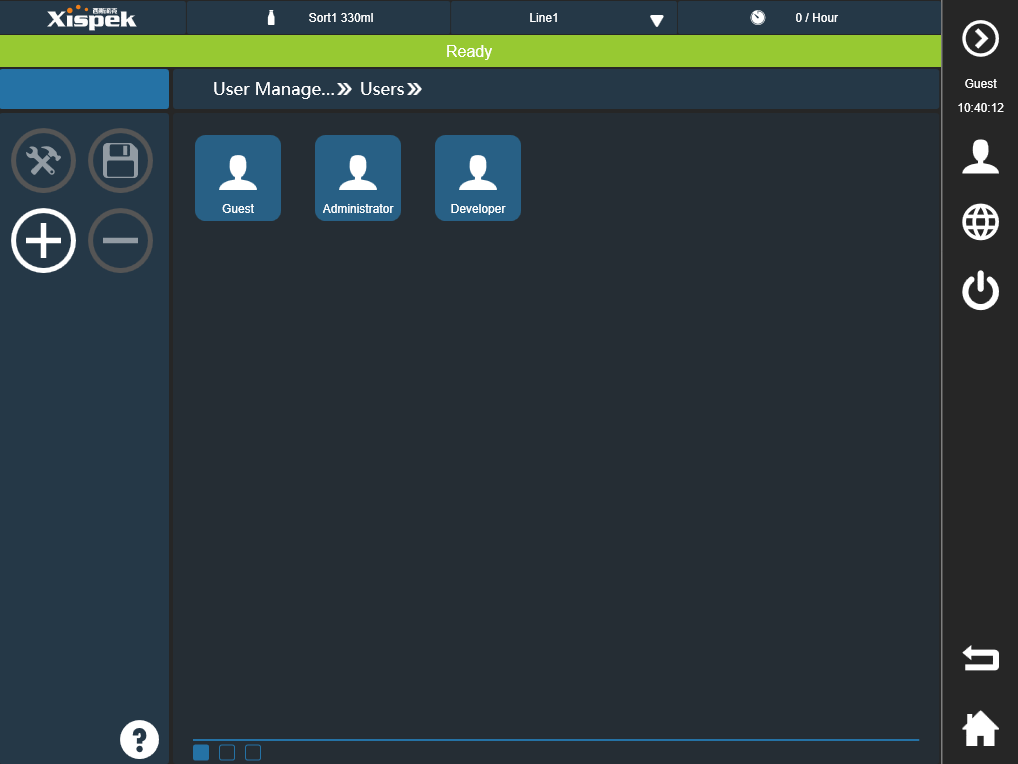

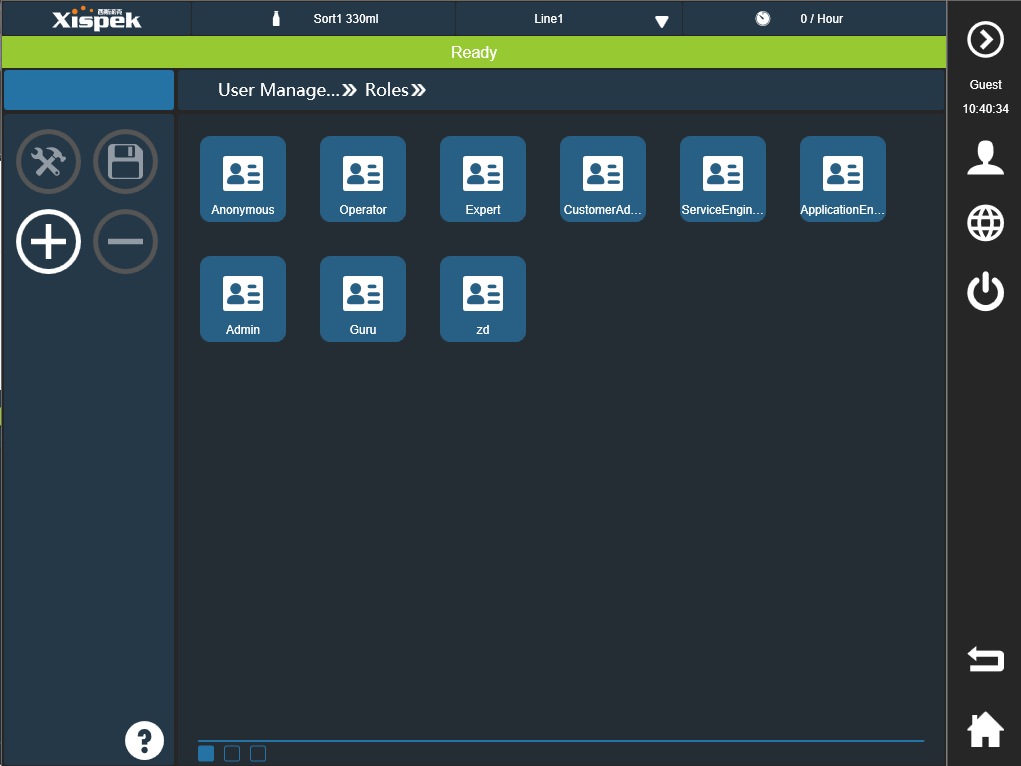

8 types of permission settings

8 types of permission settings

3 levels of user management

3 levels of user management

Customization of permissions and users

Customization of permissions and users

|

|

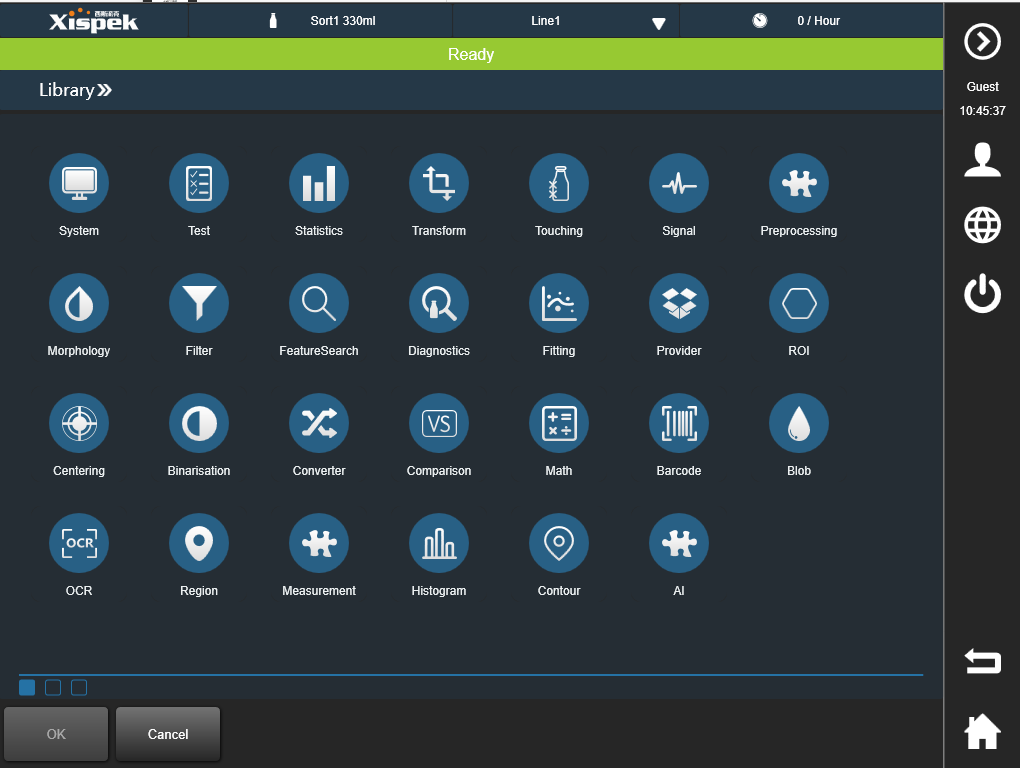

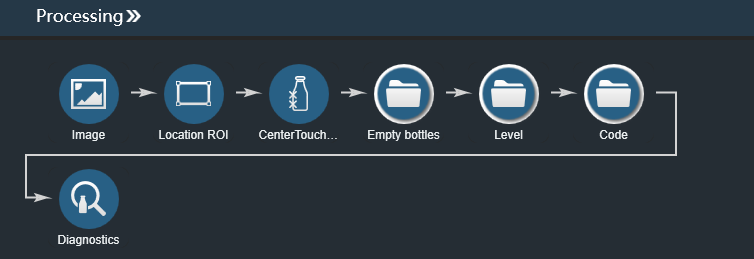

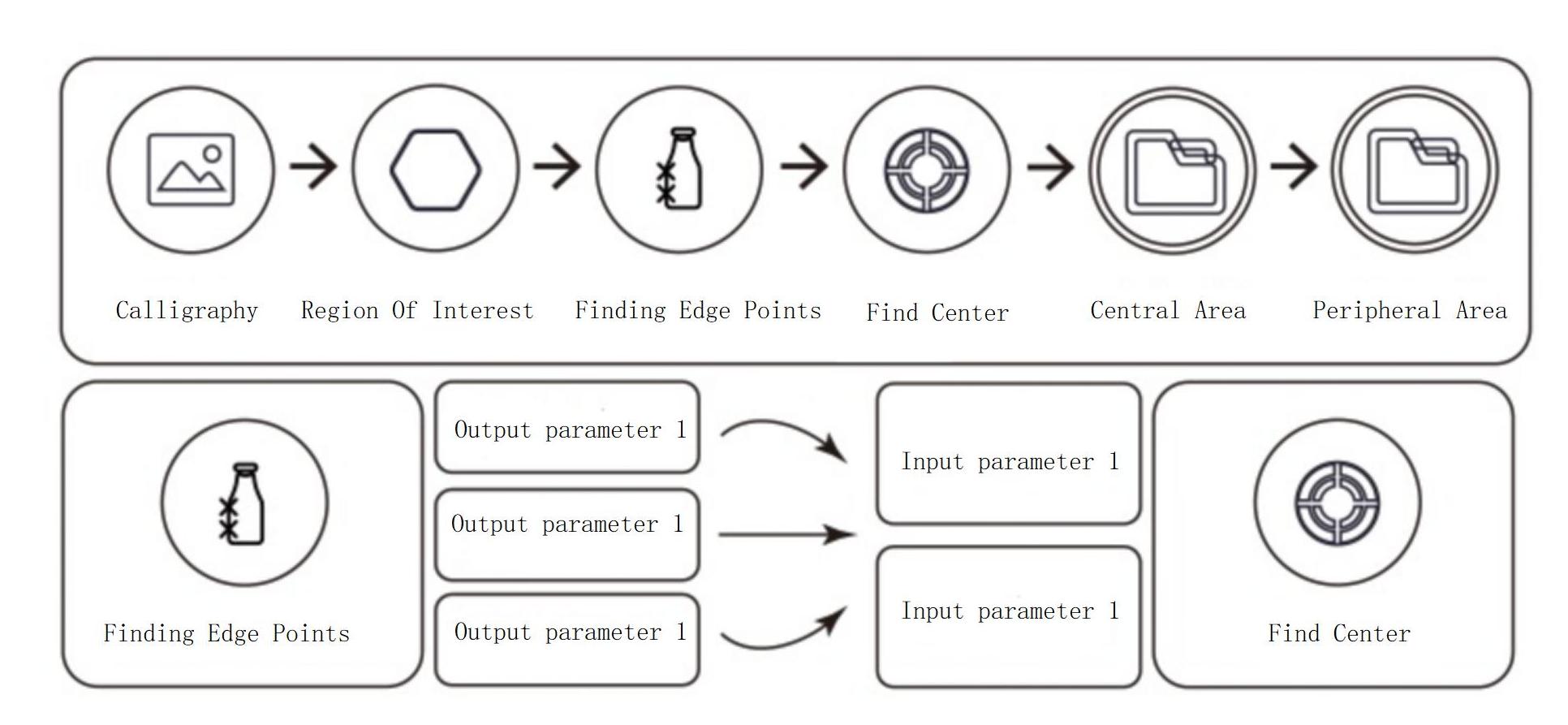

XispVision® has a complete industrial image processing library with 25 algorithmic sublibraries and over 100 algorithms. These algorithms can be used like building blocks to build specific inspection applications through inspection chaining technology. The image processing library has an open design, so it is possible to add your own algorithms in addition to the existing algorithms and to import commercial image processing libraries.

For in-line inspection systems, especially high-speed inspection systems, real-time control is a very important key. Not only does the trigger of the camera have to be at the right point in time, but also the rejection of non-conforming products requires stable and accurate tracking control.The XispVision® platform already includes a description implementation of TrackML and an interpreter implementation of XispAutomation. The system's tracking control settings are not programmable, what you see is what you get. Inspection objects can be defined online, and a series of controls such as photographing, rejecting, grasping or transmitting signals at specific locations can be performed. For details, please refer to the introduction of TrackML.

1. TrackML®-based automatic object tracking technology

Solve the following problems:

Real-time tracking on high-speed production lines

Real-time tracking on high-speed production lines

Stability over long distances

Stability over long distances

Flexibility to be applied to different production line control systems

Flexibility to be applied to different production line control systems

Diagnostic functions to ensure the accuracy of high-speed inspection

Diagnostic functions to ensure the accuracy of high-speed inspection

2. Detection chain technology and a set of common algorithm library

The following problems are solved:

Possibility of using the same inspection platform for all inspection devices

Possibility of using the same inspection platform for all inspection devices

Shortening of the development cycle for new equipment

Shortening of the development cycle for new equipment

Easily expandable with new inspection functions

Easily expandable with new inspection functions

Cross-line and even cross-industry capability of the system

Cross-line and even cross-industry capability of the system

3. Parallel computing techniques

Solve the following problems:

Reducing the time for solving a single problem and improving the efficiency of the system

Reducing the time for solving a single problem and improving the efficiency of the system

Increase the scale of problem solving

Increase the scale of problem solving

Fault tolerance, higher availability, increased system throughput rate

Fault tolerance, higher availability, increased system throughput rate

Continuous improvement of system computing power by expanding computing units

Continuous improvement of system computing power by expanding computing units

One software package for all inspection devices

One software package for all inspection devices

Support for XispSmart smart cameras

Support for XispSmart smart cameras

Universal HMI and operating modes

Universal HMI and operating modes

High and stable inspection efficiency

High and stable inspection efficiency

Expandable computing units on demand

Expandable computing units on demand

Universal data interface

Universal data interface

Easy tracking programming with TrackML® technology

Easy tracking programming with TrackML® technology

Easy to learn and use Xispek software

Easy to learn and use Xispek software

Xispek offers different levels of training for the XispVision® inspection software platform.