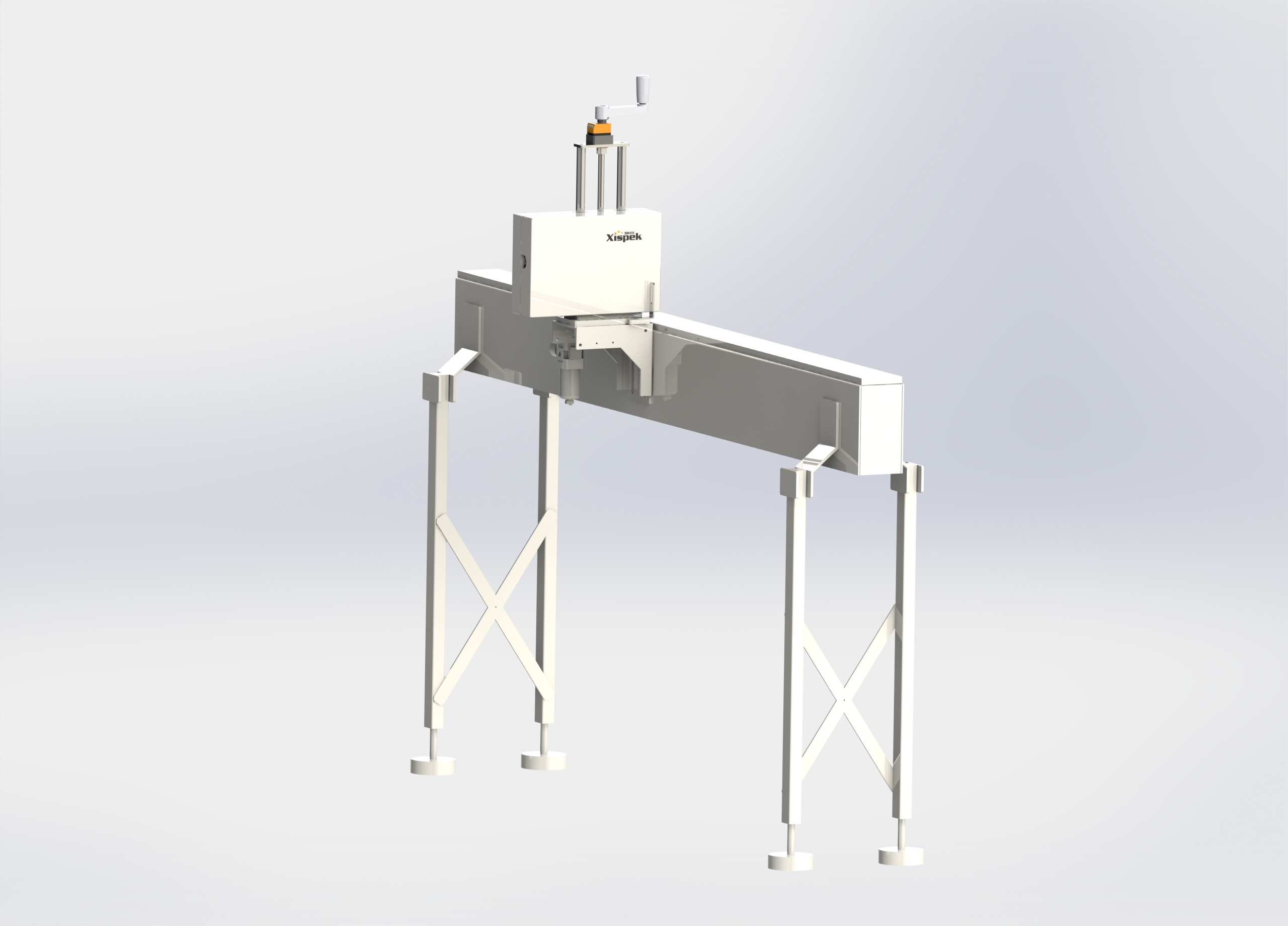

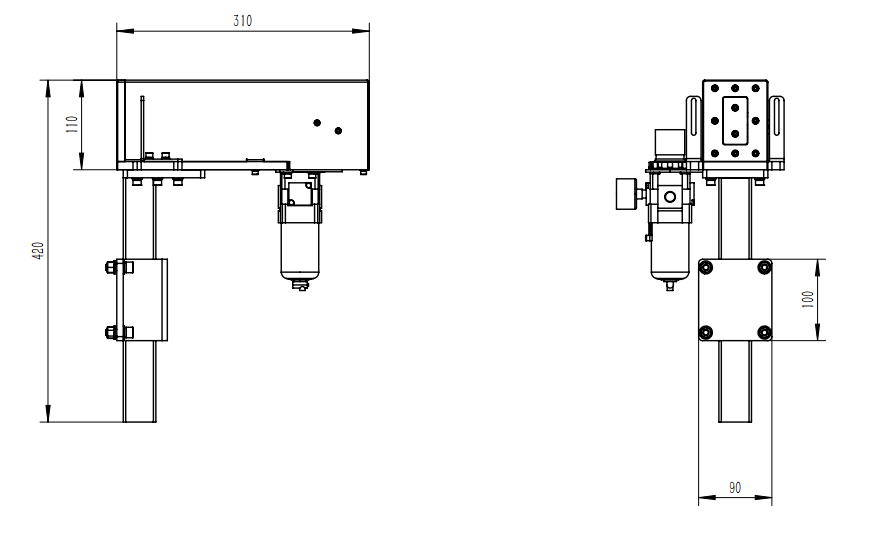

Pneumatic Rejector PU-72 is a device for separating qualified products from defective products. It controls the cylinder to expand and contract back and forth by controlling the opening and closing of the solenoid valve to reject the defective products from the production line. With simple structure and easy operation, the pneumatic rejector is widely used in various industrial production processes to improve production efficiency and product quality.

|

Scope of application:

|

Installationposition:

|

Defective products rejection

Defective products rejection

The Pneumatic Rejector PU-72 rejects defective or unqualified products from the production line to ensure that only qualified products move on to the next process. When Xispek inspection system detects defective or unqualified products, it will control the speed and distance of the cylinder forward by tracking the products to be unqualified to the designated position, and control the speed and distance of the cylinder forward by the time of solenoid valve opening to kick these unqualified products out of the production line, and the rejected products will be sent to a special collection container or another conveyor, which will separate them from the qualified products. Used in conjunction with other inspection modules, speeds of up to 72,000 BPH can be achieved.

Adpots XispVision® universal inspection software platform

Adpots XispVision® universal inspection software platform

Precise rejection with controlled intensity

Precise rejection with controlled intensity

Compact design for easy integration

Compact design for easy integration

Low cost, easy to install and maintain

Low cost, easy to install and maintain