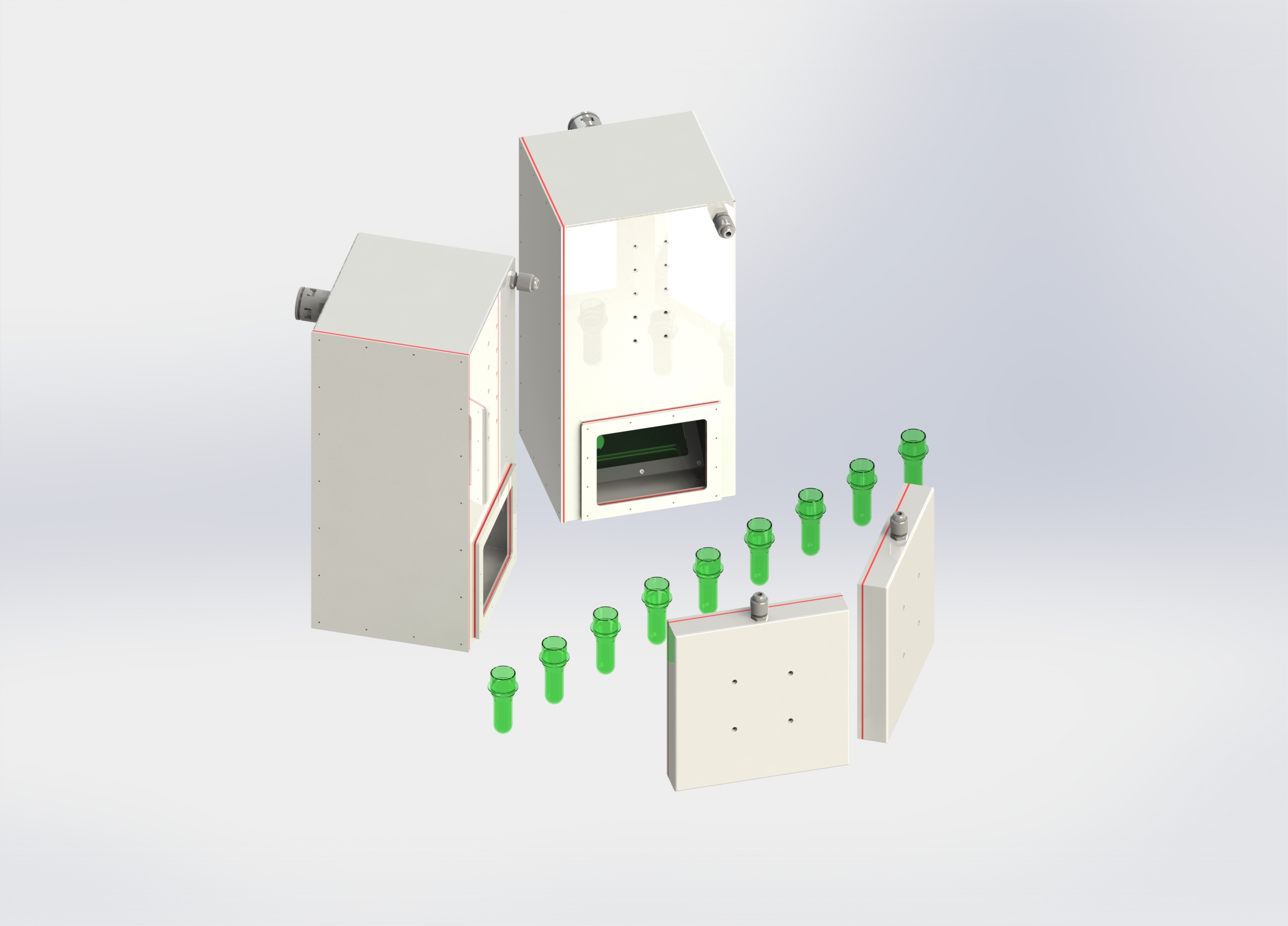

Preform Body Inspection Module is installed inside the blowing machine, using high-quality industrial cameras and maintenance-free LED light source to take pictures of preform. The overall design is compact and flexible.

|

Scope of application:

|

Installation position:

|

Black spots and bubbles

Black spots and bubbles

Contour deformation

Contour deformation

Contamination

Contamination

|

|

|

|

Normal shape |

Black spots, bubbles |

Contour deformation |

|

|

|

|

Contamination |

|

|

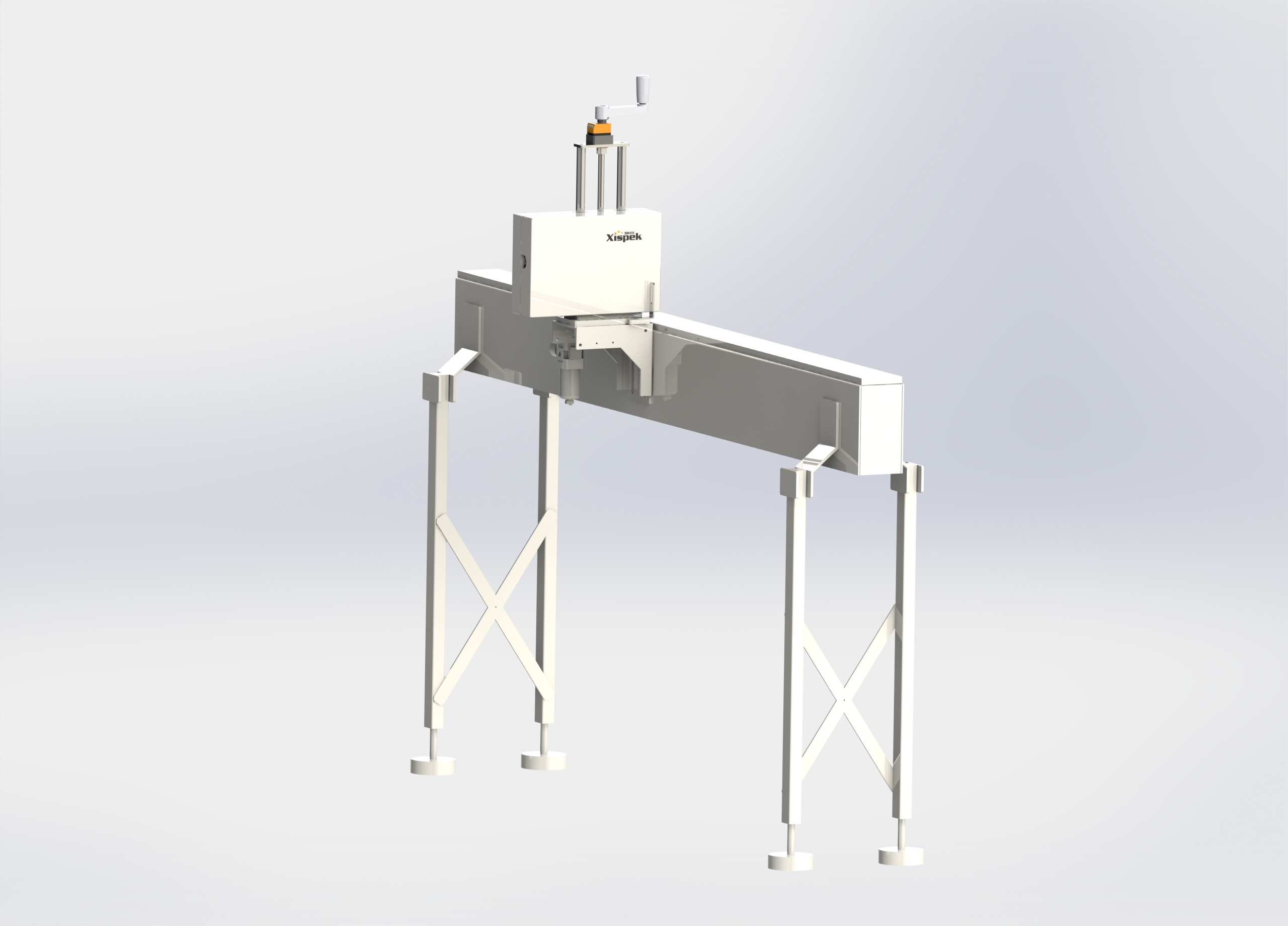

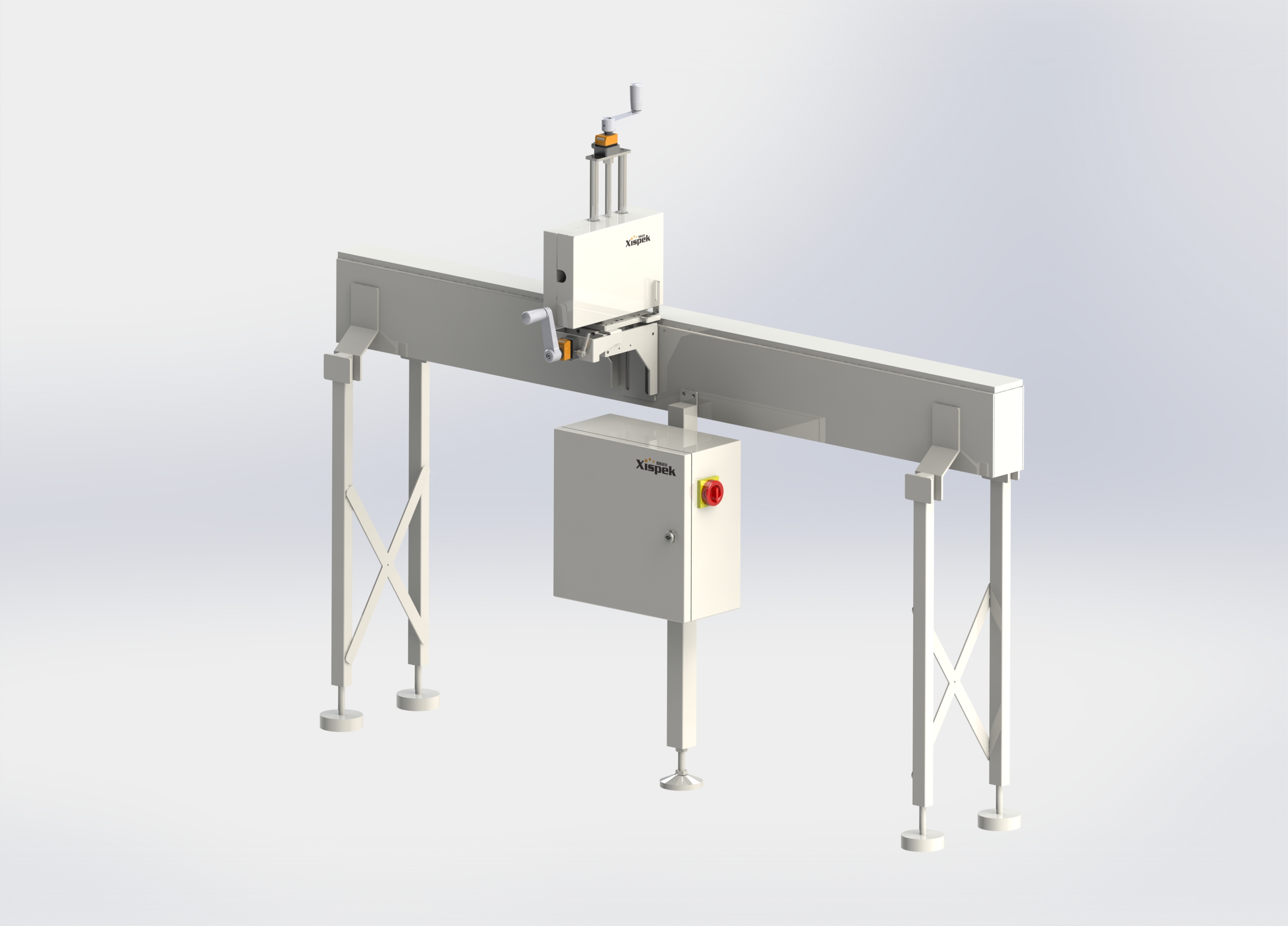

The Preform Body Inspection Module PWS is installed inside the blowing machine of the PET production line, after the preforms have been arranged and before the blowing of the bottles. The compact and modular design makes it possible to be installed in different sizes of blowing machines, and the installation position of the inspection module is very flexible. The two cameras are backlit at an angle of 90 degrees to take pictures. At the same time, it can be equipped with the inspection module of embryo finish and base module, so that the embryo can be inspected in all directions. According to different production line speed can choose different control center, can realize the highest speed of 72000bph.

Adpots XispVision® universal inspection software platform

Adpots XispVision® universal inspection software platform

High inspection efficiency and inspection accuracy

High inspection efficiency and inspection accuracy

Compact design for easy integration

Compact design for easy integration

Inspection module with IP65 protection level

Inspection module with IP65 protection level

Customized configurations are available based on customer requirements

Customized configurations are available based on customer requirements

Flexible and adaptable installation

Flexible and adaptable installation